Full lift safety valve. Flanged connections. Nodular iron or steel. Metallic seated disc. DN20/40-200/300, PN16-40.

| Dimension range | DN 20-200 |

|---|---|

| PN | 40 |

| Temperature range | -85°C to +450 ºC |

| Material | Nodular iron, Steel |

| Article number | Amount |

|---|---|

| AT 4550 |

| Dimension range | PN | Temperature range | Material |

|---|---|---|---|

| DN 25-100 | 40 | -60°C to +350 ºC | Nodular iron |

| DN 200 | 25 | -60°C to +350 ºC | Nodular iron |

| DN 20-150 | 40 | -85°C to +450 ºC | Steel |

| DN 200 | 25 | -85°C to +450 ºC | Steel |

Approved by TÜV and several other classification authorities.

Fulfils the requirements according to ISO 4126.

Certificate SS-EN 10204, type 2, 3 and from most of the classification authorities.

Type of certificate has to be specified upon ordering.

CE-marking

Meets the requirements in AFS 2016:1 and 2014/68/EU (Pressure Equipment Directive) according to category IV, fluids group 1 and 2.

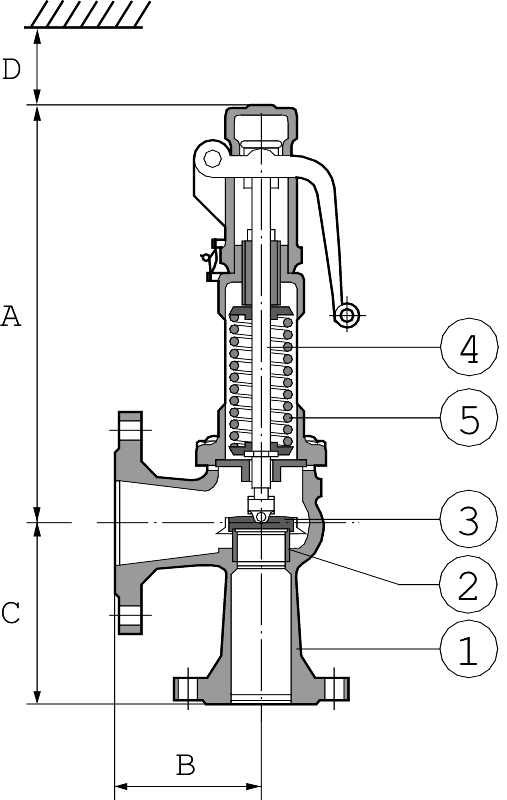

| 1 | Body | 0.7043/nodular iron Gr.60-40-18 resp. 1.0619/SA 216 WCB/steel |

| 2 | Seat | 1.4404/316L |

| 3 | Disc | 1.4122/hardened stainless steel |

| 4 | Spindle | 1.4021/420 |

| 5 | Spring | 1.1200, 1.8159, 1.7102/carbon steel |

| 5 | Spring (for temp>200oC) | 1.4310/stainless steel |

| 6 | Guide | 1.4104 tenifer/chrome steel tenifer |

| 7 | Bonet | 0.7040, 0.7043, 1.0619/nodular iron Gr.60-40-18, SA 216 WCB/steel |

| 8 | Spring plate 2 pcs | 1.0718/steel |

| 9 | Adjusting screw | 1.4104 PTFE/chrome steel PTFE |

| 10 | Ball | 1.3541/hardened stainless steel |

| 11 | Lifting device (3) | 1.0718, 0.7043/12L13 or Gr.60-40-18 |

| DN Inlet | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | |||||||||||

| DN Outlet | 40 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | |||||||||||

| Flow diameter | 18 | 23 | 29 | 37 | 46 | 60 | 74 | 92 | 98 | 125 | 165 | |||||||||||

| A | 219 | 234 | 331 | 372 | 419 | 529 | 606 | 663 | 663 | 798 | 1090 | |||||||||||

| *A with bellows | 252 | 273 | 373 | 410 | 465 | 599 | 665 | 719 | 719 | 856 | 1090 | |||||||||||

| B | 95 | 100 | 110 | 115 | 120 | 140 | 160 | 180 | 200 | 225 | 300 | |||||||||||

| C | 85 | 105 | 115 | 140 | 150 | 170 | 195 | 220 | 250 | 285 | 290 | |||||||||||

| D | 150 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 450 | 450 | 700 | |||||||||||

| Weight | 9 | 9 | 12 | 16 | 22 | 32 | 56 | 75 | 85 | 131 | 285 | |||||||||||

| *Weight with bellows | 9,4 | 10 | 13 | 17 | 24 | 36 | 60 | 83 | 93 | 142 | 289 | |||||||||||

| Dimensions in mm, weights in kg. * For valves with bellows and gas tight bonnets see separate sheet AT4547, 4548 | ||||||||||||||||||||||

Pressure increase

The safety valve is fully open at an overpressure exceeding the set pressure with a maximum of 5 %.

For set pressure lower than 1,0 bar, the overpressure is set pressure + 0,1 bar.

If lower overpressure is requested please contact Armatec.

| Steam: | Max 10% at set pressure > 3,0 barg | |

| Max 0,3 bar at set pressure ≤ 3,0 bar | ||

| If lower blowdown pressures are required please contact Armatec. | ||

| AT 4550GGG (nodular iron) | AT 4550 (steel) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Set pressure max. | Temp. | Set pressure max. | Temp. | |||||||||

| DN | bar | -60°C to +350°C | bar | -85°C to +450°C | ||||||||

| 20 | 29 | 32 | ||||||||||

| 25 | 29 | 32 | ||||||||||

| 32 | 29 | 32 | ||||||||||

| 40 | 29 | 32 | ||||||||||

| 50 | 29 | 32 | ||||||||||

| 65 | 29 | 32 | ||||||||||

| 80 | 29 | 32 | ||||||||||

| 100 | 29 | 32 | ||||||||||

| 125 | 16 | 28 | ||||||||||

| 150 | 16 | 17(25) | ||||||||||

| 200 | 20(25) | 20(25) | ||||||||||

Pressure and temperatures according to applied standards for each valve material. | ||||||||||||

| AT 4550 is a metallic seated valve. If a soft-sealed valve is requested please see separate leaflet, AT 4542/4545/4581. |

Sizing based on submitted data can be performed on request.

Please state: Capacity/power, maximum temperature (for superheated temperature) and set pressure.

For fluids other than steam, see separate leaflet series AT 4541.

Bar implies bar gauge: bar(ö), bar(g), bar(e), atö or kg/cm2 if nothing else is stated.

Coefficient of performance steam/gas, αd D/G

0,7

Coefficient of performance liquids, αd F

0,45

Flow diameter (Do), see table Dimension and Weight.

| DN | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | ||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Seat | 18 mm | 23 mm | 29 mm | 37 mm | 46 mm | 60 mm | 74 mm | 92 mm | ||||||||||||||||||||||||||||||||||||||||||||||

| Pset | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

bar | Steam | Steam | Steam | Steam | Steam | Steam | Steam | Steam | ||||||||||||||||||||||||||||||||||||||||||||||

| 0,2 | 93 | 152 | 241 | 393 | 608 | 1033 | 1567 | 2422 | ||||||||||||||||||||||||||||||||||||||||||||||

| 0,5 | 144 | 236 | 374 | 610 | 943 | 1600 | 2433 | 3767 | ||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 210 | 342 | 544 | 887 | 1367 | 2322 | 3544 | 5478 | ||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 336 | 548 | 870 | 1411 | 2189 | 3722 | 5667 | 8756 | ||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 451 | 737 | 1167 | 1900 | 2944 | 5011 | 7622 | 11778 | ||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 563 | 919 | 1456 | 2378 | 3667 | 6244 | 9511 | 14667 | ||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 674 | 1100 | 1744 | 2844 | 4400 | 7489 | 11333 | 17556 | ||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 784 | 1278 | 2033 | 3311 | 5122 | 8711 | 13222 | 20444 | ||||||||||||||||||||||||||||||||||||||||||||||

| 7 | 896 | 1456 | 2322 | 3778 | 5844 | 9944 | 15111 | 23333 | ||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 1006 | 1633 | 2600 | 4244 | 6567 | 11111 | 16889 | 26222 | ||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 1111 | 1811 | 2889 | 4711 | 7278 | 12333 | 18778 | 29111 | ||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 1222 | 2000 | 3178 | 5178 | 8000 | 13556 | 20667 | 32000 | ||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 1440 | 2356 | 3744 | 6100 | 9433 | 16000 | 24333 | 37667 | ||||||||||||||||||||||||||||||||||||||||||||||

| 14 | 1656 | 2711 | 4322 | 7033 | 10867 | 18444 | 28111 | 43444 | ||||||||||||||||||||||||||||||||||||||||||||||

| 16 | 1878 | 3078 | 4889 | 7967 | 12222 | 20889 | 31778 | 49222 | ||||||||||||||||||||||||||||||||||||||||||||||

| 18 | 2100 | 3433 | 5456 | 8889 | 13667 | 23333 | 35556 | 55000 | ||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 2322 | 3789 | 6033 | 9822 | 15111 | 25778 | 39222 | 60667 | ||||||||||||||||||||||||||||||||||||||||||||||

| 22 | 2544 | 4156 | 6611 | 10756 | 16556 | 28222 | 43000 | 66556 | ||||||||||||||||||||||||||||||||||||||||||||||

| 24 | 2767 | 4522 | 7189 | 11667 | 18000 | 30778 | 46778 | 72333 | ||||||||||||||||||||||||||||||||||||||||||||||

| 26 | 2989 | 4878 | 7767 | 12556 | 19444 | 33222 | 50556 | 78222 | ||||||||||||||||||||||||||||||||||||||||||||||

| 28 | 3211 | 5244 | 8344 | 13556 | 21000 | 35667 | 54333 | 84000 | ||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 3433 | 5611 | 8922 | 14444 | 22444 | 38222 | 58111 | 89889 | ||||||||||||||||||||||||||||||||||||||||||||||

| 32 | 3656 | 5978 | 9511 | 15444 | 23889 | 40667 | 61889 | 95778 | ||||||||||||||||||||||||||||||||||||||||||||||

| Pset = set pressure According to applied standards the value above should be multiplied with the safety factor 0,9. Saturated steam in kg/h. Capacities are given for an overpressure of 10% of set pressure. Contact Armatec for sizing with other fluids etc. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| DN | 125 | 150 | 200 | |||||

| Seat | 98 mm | 125 mm | 165 mm | |||||

| Pset | ||||||||

| bar | Steam | Steam | Steam | |||||

| 0,2 | 2756 | 4478 | 7811 | |||||

| 0,5 | 4278 | 6956 | 12111 | |||||

| 1 | 6211 | 10111 | 17555 | |||||

| 2 | 9933 | 16111 | 28111 | |||||

| 3 | 13333 | 21667 | 37889 | |||||

| 4 | 16667 | 27111 | 47222 | |||||

| 5 | 19889 | 32444 | 56555 | |||||

| 6 | 23222 | 37778 | 65889 | |||||

| 7 | 26444 | 43111 | 75222 | |||||

| 8 | 29778 | 48444 | 84444 | |||||

| 9 | 33000 | 53778 | 93667 | |||||

| 10 | 36222 | 59000 | 102889 | |||||

| 12 | 42778 | 69667 | 121111 | |||||

| 14 | 49333 | 80222 | 138889 | |||||

| 16 | 55889 | 90889 | 157778 | |||||

| 18 | 62333 | 101556 | 176667 | |||||

| 20 | 68889 | 111111 | 195555 | |||||

| 22 | 75444 | 123333 | 214444 | |||||

| 24 | 82111 | 133333 | 232222 | |||||

Pset = set pressure | ||||||||

Test Gag for blocking the safety valve

Lift stopper

Flanges drilled acc. to ANSI.

Back pressure compensating bellows, see separate leaflet AT 4547.

Safety valve with closed bonnet, soft sealed disc or in stainless steel please see separate leaflet series AT 4541.

Supplementary loading system, see AT4505.

| Connections | Flanges drilled acc. to | |

|---|---|---|

| AT 4550GGG (nodular iron) | ||

| Inlet/outlet | DN25-80: DIN EN 1092-1, PN40/DIN EN 1092-1, PN16 | |

| DN 100-150: DIN EN 1092-1, PN16/DIN EN 1092-1, PN16 | ||

| DN 200: DIN EN 1092-1, PN25/DIN EN 1092-1, PN10 | ||

| See separate installation and maintenance instruction. See separate installation and maintenance instruction. | ||

| Connections | Flanges drilled acc. to | |

|---|---|---|

| AT 4550 (steel) | ||

| Inlet/outlet | DN20-130: DIN EN 1092-1, PN40/DIN EN 1092-1, PN16 | |

| DN200: DIN EN 1092-1, PN25/DIN EN 1092-1, PN16 | ||

| See separate installation instruction. The valve should be mounted with the bonnet in vertical position. | ||

| Metal seated safety valve with open bonnet | |||

| Example: AT 4550-3-18,0-25 | |||

| AT 4550 | -3 | -18,0 | -25 |

|---|---|---|---|

| Fig. nr. | Design | Set pressure (barg) | DN |

| AT 4550GGG=nodular iron | -3=open lifting device | ||

V3=open lifting device and bellows | |||

| AT 4550=stål | -2=cap (no lifting device) | ||

| V2=cap (no lifting device) and bellows |