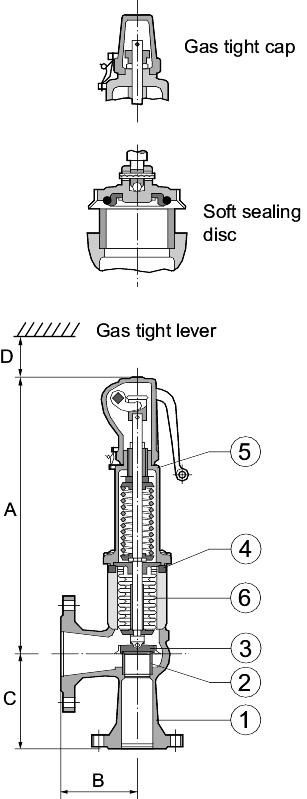

Full lift safety valve. Flanged connections. Steel or stainless steel. Soft- or metallic seated disc. DN20/40-200/300 (stainless DN25/40-150/250), PN40. Back-pressure compensating bellows of stainless steel.

| Dimension range | 20-200 |

|---|---|

| PN | 40 |

| Temperature range | -270 to +450°C |

| Material | Steel, stainless steel |

| Article number | Amount |

|---|---|

| AT 4547 | |

| AT 4548 | |

| AT 4583 | |

| AT 4584 |

| Dimension range | PN | Temperature range | Material |

|---|---|---|---|

| DN 20-150 | 40 | -85°C to +450 ºC | Steel |

| DN 200 | 25 | -85°C to +450 ºC | Steel |

| DN 20-150 | 40 | -270°C to +400 ºC | Stainless steel |

| DN200 | 25 | -270°C to+400 ºC | Stainless steel |

Safety valve for protection of pressure vessels and piping systems with liquids, air, gases and steam.

Provided with back-pressure compensating and sealing stainless steel bellows. This raises the maximum allowable back-pressure in the outlet from 15 % to 30-35 % of the set pressure. The design pressure of the bellows must however be taken into account. See Additional information.

With back-pressure compensating bellows, the outlet dimension can be kept down.

Bellows are also recommended when the safety valve is to be connected to a silencer.

PSG. 11 Safety valve

Safety valve with back pressure compensating bellows AT4547, DN ..., set pressure... bar, stainless steel.

Approved by TÜV and several other classification authorities.

Fulfils the requirements according to ISO 4126.

Certificate SS-EN 10204, type 2, 3 and from most of the classification authorities.

Type of certificate has to be specified upon ordering.

CE-marking

Meets the requirements in AFS 2016:1 and 2014/68/EU (Pressure Equipment Directive) according to category IV, fluids group 1 and 2.

| AT 4547/AT 4548 | AT 4583/AT 4584 | ||

|---|---|---|---|

| 1 | Body | 1.0619/SA 216 WCB, steel | 1.4408/SA 351 CF8M, stainless steel |

| 2 | Seat | 1.4404/316L | 1.4404/316L |

| 3 | Disc | 1.4122/hardened stainless steel | 1.4404/316L |

| 4 | Spindle | 1.4021/420 | 1.4404/316L |

| 5 | Spring | 1.1200, 1.8159, | 1.4310/stainless steel |

| 1.7102/carbon steel | |||

| 6 | Bellows | 1.4571/316Ti | 1.4571/316Ti |

| 7 | Guide | 1.4104, 1.0501, 0.7040/ | 1.4404/316L |

| chrome- or carbon steel | |||

| 8 | Bonnet | 0.7040, 0.7043, 1.0619/ | 1.4408, 1.4404, 1.4571/ |

| nodular iron Gr.60-40-18, | SA 351 CF8M, SA 479 316L, | ||

| SA 216 WCB | SA 479 316Ti | ||

| 9 | Spring plate 2 pcs | 1.0718/steel | 1.4404/316L |

| 10 | Adjusting screw | 1.4104 PTFE/ | 1.4404 PTFE/316L PTFE |

| chrome steel PTFE | |||

| 11 | Ball | 1.3541/hardened stainless steel | 1.4401/316 |

| 12a | Cap | 1.0718 or 0.7043/12L13 | 1.4404/316L |

| or Gr.60-40-18 | |||

| 12b | Lever (4) | 1.0718 or 0.7043/12L13 | 1.4404/316L |

| or Gr.60-40-18 | |||

| 13a | Soft sealing | EPDM (D) | EPDM (D) |

| 13b | Soft sealing | Neoprene (K) | Neoprene (K) |

| 13c | Soft sealing | Viton® (L) | Viton® (L) |

| 14 | Bonnet spacer | 1.0460/ carbon steel | 1.4404/316L |

| for bellow |

| AT 4547, 4548 | ||||||||||||||||||||||

| DN Inlet | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | |||||||||||

| DN Outlet | 40 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | |||||||||||

| Seat diameter | 18 | 23 | 29 | 37 | 46 | 60 | 74 | 92 | 98 | 125 | 165 | |||||||||||

| A | 252 | 273 | 373 | 410 | 465 | 599 | 665 | 719 | 719 | 856 | 1090 | |||||||||||

| B | 95 | 100 | 110 | 115 | 120 | 140 | 160 | 180 | 200 | 225 | 300 | |||||||||||

| C | 85 | 105 | 115 | 140 | 150 | 170 | 195 | 220 | 250 | 285 | 290 | |||||||||||

| D | 150 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 450 | 450 | 700 | |||||||||||

| Weight | 9,4 | 10 | 13 | 17 | 24 | 36 | 60 | 83 | 93 | 142 | 289 | |||||||||||

| Measurements in mm, weight in kg. (2)= gas tight cap, (4)= gas tight lifting device. | ||||||||||||||||||||||

| AT 4583, 4584 | ||||||||||||||||||

| DN Inlet | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | |||||||||

| DN Outlet | 40 | 50 | 65 | 80 | 100 | 25 | 150 | 200 | 250 | |||||||||

| Flow diameter | 23 | 29 | 37 | 46 | 60 | 74 | 92 | 98 | 125 | |||||||||

| A max | 273 | 373 | 410 | 465 | 599 | 665 | 719 | 719 | 856 | |||||||||

| B | 100 | 110 | 115 | 120 | 140 | 160 | 180 | 200 | 225 | |||||||||

| C | 105 | 115 | 140 | 150 | 170 | 195 | 220 | 250 | 285 | |||||||||

| D | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 450 | 450 | |||||||||

| Weight | 10 | 13 | 17 | 24 | 36 | 60 | 83 | 93 | 142 | |||||||||

| Measures in mm, weights in kg. (2)= gastight cap (4)= gastight lifting device. | ||||||||||||||||||

Spring loaded and directly acting safety valve for air, gases and steam with full lift opening characteristics.

For liquids, the safety valve has normal opening characteristics.

With lifting device for manual testing or with gas tight cap.

If possible, a soft sealing disc should be used since it has better tightness and is easier to renovate.

The bellows protect the moving parts and spring against dirt, corrosion and temperature, and permit an increased maximum back-pressure in the outlet pipe from 15 % to 30-35 % of the set pressure.

The bellows design pressure must be considered. See Additional information.

Blowdown

| Steam/air/gases: | Max 10% at set pressure ≥ 3,0 bar | |

| Max 0,3 bar at set pressure < 3,0 bar | ||

| Liquids: | Max 20% at set pressure ≥ 3,0 bar | |

| Max 0,6 bar at set pressure < 3,0 bar | ||

| If lower blowdown pressures are required please contact Armatec. | ||

| AT 4547/AT 4548 | AT 4583/AT 4584 | |||||||

| Set pressure max. | Temp. -85°C | Set pressure max. | Temp. -85°C | |||||

| DN | bar | to +450°C | bar | to +400°C | ||||

| 20 | 40 | - | ||||||

| 25 | 40 | 40 | ||||||

| 32 | 40 | 40 | ||||||

| 40 | 40 | 40 | ||||||

| 50 | 40 | 37 | ||||||

| 65 | 40 | 28 | ||||||

| 80 | 40 | 25 | ||||||

| 100 | 40 | 26 | ||||||

| 125 | 25 | 24 | ||||||

| 150 | 25 | 10 | ||||||

| 200 | 25 | - | ||||||

| Pressure and temperatures according to applied standards for each valve material. At temperatures above 200°C the temperature has to be specified in the order, so that a high temperature spring is used. If other temperatures and pressures limits are requested please contact Armatec. | ||||||||

| Temperature range soft sealed safety valves: | |

| O-ring | Neoprene (CR) K -40°C to +100°C, e.g refrigants |

| Ethylene (EPDM) D -45°C to +150°C, e.g hot water and low temperature steam | |

| Viton (FPM) L -20°C to +180°C, e.g oil and air |

Sizing based on submitted data can be performed on request.

Please state: Fluid, density (for liquids), capacity/power, maximum temperature and set pressure

Bar implies bar gauge: bar(ö), bar(g), bar(e), atö or kg/cm2 if nothing else is stated.

Nm3/h implies "free" capacity air/gas (N=normal) and is equal with m3/h if other is not stated.

Coefficient of discharge steam/gases αd D/G

0,7

Coefficient of discharge liquids, αd F

0,45

Flow diameter Do, see Dimension and Weight

Lowest set pressure for valve with bellows:

3,0 barg (DN20-80)

2,74 barg (DN100)

2,01 barg (DN125)

0,2 barg (DN150-200)

| Max. pressure bar | At 20°C | At 100°C | At 200°C | At 400°C |

| DN20 | 30 | 28 | 24 | 20 |

| DN25 | 16 | 15 | 13 | 11 |

| DN32-125 | 10 | 9,3 | 8 | 6,6 |

| DN150 | 6 | 5,6 | 4,8 | 4 |

| DN200 | 5 | 4,7 | 4 | 3,3 |

| DN | 20 | 25 | 32 | 40 | 50 | ||||||||||||||||||||||||||||||||||||||

| Seat | 18 mm | 23 mm | 29 mm | 37 mm | 46 mm | ||||||||||||||||||||||||||||||||||||||

| Pset | |||||||||||||||||||||||||||||||||||||||||||

bar | Steam | Air | Water | Steam | Air | Water | Steam | Air | Water | Steam | Air | Water | Steam | Air | Water | ||||||||||||||||||||||||||||

| 3 | 451 | 580 | 11778 | 737 | 947 | 19222 | 1167 | 1500 | 30556 | 1900 | 2444 | 49667 | 2944 | 3778 | 76778 | ||||||||||||||||||||||||||||

| 4 | 563 | 728 | 13556 | 919 | 1178 | 22111 | 1456 | 1889 | 35222 | 2378 | 3067 | 57333 | 3667 | 4744 | 88667 | ||||||||||||||||||||||||||||

| 5 | 674 | 876 | 15222 | 1100 | 1422 | 24778 | 1744 | 2267 | 39444 | 2844 | 3700 | 64111 | 4400 | 5711 | 99111 | ||||||||||||||||||||||||||||

| 6 | 784 | 1024 | 16667 | 1278 | 1667 | 27111 | 2033 | 2656 | 43111 | 3311 | 4322 | 70222 | 5122 | 6689 | 108556 | ||||||||||||||||||||||||||||

| 7 | 896 | 1167 | 18000 | 1456 | 1911 | 29333 | 2322 | 3033 | 46667 | 3778 | 4944 | 75889 | 5844 | 7656 | 117778 | ||||||||||||||||||||||||||||

| 8 | 1006 | 1311 | 19222 | 1633 | 2156 | 31333 | 2600 | 3422 | 49778 | 4244 | 5578 | 81111 | 6567 | 8622 | 125556 | ||||||||||||||||||||||||||||

| 9 | 1111 | 1467 | 20333 | 1811 | 2389 | 33222 | 2889 | 3811 | 52889 | 4711 | 6200 | 86000 | 7278 | 9589 | 133333 | ||||||||||||||||||||||||||||

| 10 | 1222 | 1611 | 21444 | 2000 | 2633 | 35000 | 3178 | 4189 | 55667 | 5178 | 6833 | 90667 | 8000 | 10556 | 140000 | ||||||||||||||||||||||||||||

| 12 | 1440 | 1911 | 23556 | 2356 | 3122 | 38444 | 3744 | 4967 | 61000 | 6100 | 8078 | 99333 | 9433 | 12444 | 153333 | ||||||||||||||||||||||||||||

| 14 | 1656 | 2200 | 25444 | 2711 | 3600 | 41444 | 4322 | 5733 | 65889 | 7033 | 9333 | 107333 | 10867 | 14333 | 165556 | ||||||||||||||||||||||||||||

| 16 | 1878 | 2500 | 27111 | 3078 | 4089 | 44333 | 4889 | 6500 | 70444 | 7967 | 10589 | 114444 | 12222 | 16333 | 177778 | ||||||||||||||||||||||||||||

| 18 | 2100 | 2800 | 28778 | 3433 | 4567 | 47000 | 5456 | 7267 | 74778 | 8889 | 11778 | 122222 | 13667 | 18222 | 187778 | ||||||||||||||||||||||||||||

| 20 | 2322 | 3089 | 30333 | 3789 | 5056 | 49556 | 6033 | 8044 | 78778 | 9822 | 13000 | 127778 | 15111 | 20222 | 197778 | ||||||||||||||||||||||||||||

| 22 | 2544 | 3389 | 31889 | 4156 | 5544 | 52000 | 6611 | 8811 | 82667 | 10756 | 14333 | 134444 | 16556 | 22111 | 207778 | ||||||||||||||||||||||||||||

| 24 | 2767 | 3689 | 33222 | 4522 | 6022 | 54333 | 7189 | 9578 | 86333 | 11667 | 15556 | 140000 | 18000 | 24111 | 216667 | ||||||||||||||||||||||||||||

| 26 | 2989 | 3989 | 34556 | 4878 | 6511 | 56556 | 7767 | 10344 | 89889 | 12556 | 16778 | 146667 | 19444 | 26000 | 225556 | ||||||||||||||||||||||||||||

| 28 | 3211 | 4278 | 35889 | 5244 | 6989 | 58667 | 8344 | 11111 | 93222 | 13556 | 18000 | 152222 | 21000 | 27889 | 234444 | ||||||||||||||||||||||||||||

| 30 | 3433 | 4578 | 37222 | 5611 | 7478 | 60667 | 8922 | 11889 | 96444 | 14444 | 19333 | 156667 | 22444 | 29889 | 243333 | ||||||||||||||||||||||||||||

| 32 | 3656 | 4878 | 38444 | 5978 | 7956 | 62667 | 9511 | 12556 | 99667 | 15444 | 20556 | 162222 | 23889 | 31778 | 251111 | ||||||||||||||||||||||||||||

| 34 | - | 5167 | 39556 | - | 8444 | 64667 | - | 13333 | 102778 | - | 21778 | 167778 | - | 33778 | 258889 | ||||||||||||||||||||||||||||

| 36 | - | 5467 | 40778 | - | 8933 | 66444 | - | 14111 | 105667 | - | 23111 | 172222 | - | 35667 | 265556 | ||||||||||||||||||||||||||||

| 38 | - | 5767 | 41889 | - | 9411 | 68333 | - | 14889 | 108556 | - | 24333 | 176667 | - | 37667 | 273333 | ||||||||||||||||||||||||||||

| 40 | - | 6056 | 42889 | - | 9900 | 70111 | - | 15667 | 111111 | - | 25556 | 181111 | - | 39556 | 280000 | ||||||||||||||||||||||||||||

| Pset = set pressure According to applied standards the value above should be multiplied with the safety factor 0,9. Saturated steam in kg/h. Air in Nm3/h (free air) at 0ºC and atmospheric pressure 1013 mbar(a). Water in kg/h at 20ºC. Capacities are given for an overpressure of 10% of set pressure. Contact Armatec for sizing with other fluids etc. | |||||||||||||||||||||||||||||||||||||||||||

| DN | 65 | 80 | 100 | |||||||||||||||

| Seat | 60 mm | 74 mm | 92 mm | |||||||||||||||

| Pset | ||||||||||||||||||

| bar | Steam | Air | Water | Steam | Air | Water | Steam | Air | Water | |||||||||

| 2 | 3722 | 4733 | 106667 | 5667 | 7211 | 162222 | 8756 | 11111 | 251111 | |||||||||

| 3 | 5011 | 6433 | 131111 | 7622 | 9789 | 198889 | 11778 | 15111 | 306667 | |||||||||

| 4 | 6244 | 8078 | 151111 | 9511 | 12222 | 228889 | 14667 | 19000 | 354444 | |||||||||

| 5 | 7489 | 9733 | 168889 | 11333 | 14778 | 256667 | 17556 | 22778 | 396667 | |||||||||

| 6 | 8711 | 11333 | 184444 | 13222 | 17222 | 281111 | 20444 | 26667 | 434444 | |||||||||

| 7 | 9944 | 13000 | 200000 | 15111 | 19778 | 303333 | 23333 | 30556 | 468889 | |||||||||

| 8 | 11111 | 14667 | 213333 | 16889 | 22222 | 324444 | 26222 | 34444 | 501111 | |||||||||

| 9 | 12333 | 16222 | 226667 | 18778 | 24778 | 344444 | 29111 | 38333 | 532222 | |||||||||

| 10 | 13556 | 17889 | 238889 | 20667 | 27333 | 362222 | 32000 | 42222 | 561111 | |||||||||

| 12 | 16000 | 21222 | 261111 | 24333 | 32333 | 397778 | 37667 | 49889 | 614444 | |||||||||

| 14 | 18444 | 24556 | 282222 | 28111 | 37333 | 428889 | 43444 | 57667 | 663333 | |||||||||

| 16 | 20889 | 27778 | 301111 | 31778 | 42333 | 458889 | 49222 | 65444 | 708889 | |||||||||

| 18 | 23333 | 31111 | 320000 | 35556 | 47333 | 486667 | 55000 | 73222 | 752222 | |||||||||

| 20 | 25778 | 34333 | 337778 | 39222 | 52333 | 513333 | 60667 | 80889 | 793333 | |||||||||

| 22 | 28222 | 37667 | 353333 | 43000 | 57333 | 537778 | 66556 | 88667 | 831111 | |||||||||

| 24 | 30778 | 41000 | 370000 | 46778 | 62333 | 562222 | 72333 | 96444 | 868889 | |||||||||

| 26 | 33222 | 44222 | 384444 | 50556 | 67333 | 584444 | 78222 | 105556 | 904444 | |||||||||

| 28 | 35667 | 47556 | 398889 | 54333 | 72333 | 606667 | 84000 | 113333 | 937778 | |||||||||

| 30 | 38222 | 50889 | 413333 | 58111 | 77444 | 627778 | 89889 | 121111 | 971111 | |||||||||

| 32 | 40667 | 54111 | 426667 | 61889 | 82444 | 648889 | 95778 | 128889 | 1003333 | |||||||||

| 34 | - | 57444 | 440000 | - | 88556 | 668889 | - | 136667 | 1034444 | |||||||||

| 36 | - | 61556 | 452222 | - | 93667 | 687778 | - | - | - | |||||||||

| 38 | - | 64889 | 464444 | - | 98778 | 706667 | - | - | - | |||||||||

| 40 | - | 68222 | 476667 | - | 103889 | 725556 | - | - | - | |||||||||

| Pset = set pressure According to applied standards the value above should be multiplied with the safety factor 0,9. Saturated steam in kg/h. Air in Nm3/h (free air) at 0ºC and atmospheric pressure 1013 mbar(a). Water in kg/h at 20ºC. Capacities are given for an overpressure of 10% of set pressure. Contact Armatec for sizing with other fluids etc. | ||||||||||||||||||

| DN | 125 | 150 | 200 | |||||||||||||||||||||||||||||||||

| Seat | 98 mm | 125 mm | 165 mm | |||||||||||||||||||||||||||||||||

| Pset | ||||||||||||||||||||||||||||||||||||

| bar | Steam | Air | Water | Steam | Air | Water | Steam | Air | Water | |||||||||||||||||||||||||||

| 0,2 | 2756 | 3267 | 105111 | 4478 | 5311 | 171111 | 7811 | 9267 | 255555 | |||||||||||||||||||||||||||

| 0,5 | 4278 | 5244 | 148889 | 6956 | 8533 | 242222 | 12111 | 14778 | 403333 | |||||||||||||||||||||||||||

| 1 | 6211 | 7811 | 201111 | 10111 | 12667 | 327778 | 17555 | 22111 | 570000 | |||||||||||||||||||||||||||

| 2 | 9933 | 12556 | 284444 | 16111 | 20556 | 463333 | 28111 | 35778 | 806667 | |||||||||||||||||||||||||||

| 3 | 13333 | 17111 | 348889 | 21667 | 27889 | 566667 | 37889 | 48667 | 987778 | |||||||||||||||||||||||||||

| 4 | 16667 | 21556 | 402222 | 27111 | 35000 | 654444 | 47222 | 61111 | 1144444 | |||||||||||||||||||||||||||

| 5 | 19889 | 25889 | 450000 | 32444 | 42222 | 732222 | 56555 | 73555 | 1277778 | |||||||||||||||||||||||||||

| 6 | 23222 | 30333 | 493333 | 37778 | 49333 | 802222 | 65889 | 86000 | 1400000 | |||||||||||||||||||||||||||

| 7 | 26444 | 34667 | 532222 | 43111 | 56444 | 865556 | 75222 | 98444 | 1511111 | |||||||||||||||||||||||||||

| 8 | 29778 | 39111 | 568889 | 48444 | 63667 | 925556 | 84444 | 110889 | 1611111 | |||||||||||||||||||||||||||

| 9 | 33000 | 43444 | 603333 | 53778 | 70778 | 982222 | 93667 | 123333 | 1711111 | |||||||||||||||||||||||||||

| 10 | 36222 | 47889 | 636667 | 59000 | 77889 | 1035556 | 102889 | 135555 | 1800000 | |||||||||||||||||||||||||||

| 12 | 42778 | 56667 | 696667 | 69667 | 92222 | 1133333 | 121111 | 160000 | 1977778 | |||||||||||||||||||||||||||

| 14 | 49333 | 65444 | 753333 | 80222 | 106556 | 1222222 | 138889 | 185555 | 2133333 | |||||||||||||||||||||||||||

| 16 | 55889 | 74222 | 804444 | 90889 | 120000 | 1300000 | 157778 | 210000 | 2277778 | |||||||||||||||||||||||||||

| 18 | 62333 | 83000 | 853333 | 101556 | 134444 | 1377778 | 176667 | 238889 | 2422222 | |||||||||||||||||||||||||||

| 20 | 68889 | 91778 | 900000 | 111111 | 148889 | 1455556 | 195555 | 263333 | 2555555 | |||||||||||||||||||||||||||

| 22 | 75444 | 100667 | 943333 | 123333 | 165556 | 1533333 | 214444 | 288889 | 2677778 | |||||||||||||||||||||||||||

| 24 | 82111 | 110889 | 985556 | 133333 | 180000 | 1600000 | 232222 | 314444 | 2788889 | |||||||||||||||||||||||||||

| Pset = set pressure According to applied standards the value above should be multiplied with the safety factor 0,9. Saturated steam in kg/h. Air in Nm3/h (free air) at 0ºC and atmospheric pressure 1013 mbar(a). Water in kg/h at 20ºC. Capacities are given for an overpressure of 10% of set pressure. Contact Armatec for sizing with other fluids etc. For larger valve dimensions and/or larger capacities, se separate data sheet for AT 4543 - 4580, DN 200-400 are available with bellows on request. | ||||||||||||||||||||||||||||||||||||

| Connection AT4547/4548 | Flanges drilled acc. to | |

|---|---|---|

| Inlet/outlet | DN20-150: DIN EN 1092-1, PN40/16 | |

| DN200: DIN EN 1092-1, PN25/16 | ||

| See separate installation instruction. The valve should be mounted with the bonnet in vertical position. | ||

| Metal seated safety valve with back-pressure compensating bellows. | |||

| Example: AT 4547-4-10,0-25 | |||

| AT 4547 | -4 | -10,0 | -25 |

|---|---|---|---|

| Fig. no. | Design | Set pressure(bar) | DN |

| AT 4547=steel | -2=gas tight cap | ||

| AT 4583=stainless steel | -4=gas tight lifting device | ||

| -3=open lifting device |

| Soft seated safety valve with back-pressure compensating bellows. | ||||

| Example: AT 4548D4-10,0-25 | ||||

| AT 4545 | D | 4 | -10,0 | -25 |

|---|---|---|---|---|

| Fig. no. | O-ring | Design | Set pressure (bar) | DN |

| AT 4548=steel | D=EPDM | 2=gas tight cap | ||

| AT 4584=stainless steel | L=Viton | 4=gas tight lifting device | ||

| K=Neoprene | 3=open lifting device | |||

| N=Nitrile |