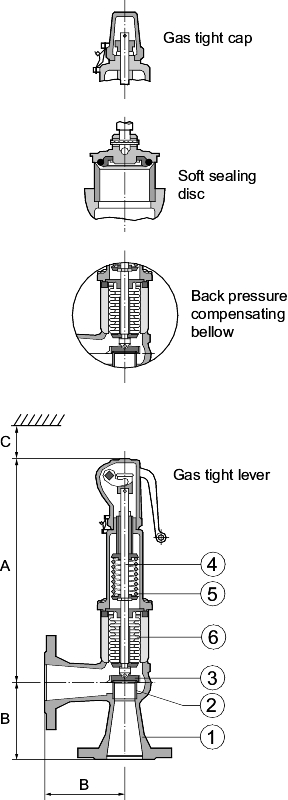

Safety valve with standard characteristics. Flanged connections. Steel or stainless steel. Soft- or metallic seated disc. DN15-150 (stainless DN15-100), PN16-40. Back pressure compensating bellows of stainless steel.

| Dimension range | 15-150 |

|---|---|

| PN | 16-40 |

| Temperature range | -270 to +450°C |

| Material | Steel, stainless steel |

| Article number | Amount |

|---|---|

| AT 4522 | |

| AT 4523 | |

| AT 4577 | |

| AT 4578 |

| Dimension range | PN | Temperature range | Material |

|---|---|---|---|

| DN 15-150 | 40 | -85ºC to +450 ºC | Steel |

| DN 15-100 | 40 | -270ºC to +400 ºC | Stainless steel |

Approved by TÜV and several other classification authorities.

Fulfils the requirements according to ISO 4126.

Certificate SS-EN 10204, type 2, 3 and from most of the classification authorities.

Type of certificate has to be specified upon ordering.

CE-marking

Meets the requirements in AFS 2016:1 and 2014/68/EU (Pressure Equipment Directive) according to category IV, fluids group 1 and 2.

| AT 4522/AT 4523 | AT 4577/AT 4578 | ||

|---|---|---|---|

1 | Body | 1.0619/SA 216 WCB | 1.4408/SA 351 CF8M |

| 2 | Seat | 1.4404/316L | 1.4404/316L |

| 3 | Disc | 1.4122/Hardened stainless steel | 1.4404/316L |

| 4 | Spindle | 1.4404/316L | 1.4404/316L |

| 5 | Spring | 1.1200,1.8159,1.7102/Spring steel | 1.4310/Stainless steel |

| 6 | Bellows | 1.4571/316Ti | 1.4571/316Ti |

| Bonnet spacer | 1.4404/316L | 1.4404/316L | |

| 7 | Guide | 1.4104,1.0501,1.0570/Chrome- or stainless steel | 1.4404/316L |

| Bushing for guide | 1.4104 tenifer/Chrome steel | - | |

| 8 | Bonnet | 1.7040/Nodular iron Gr.60-40-18 | 1.4408,1.4404/ |

| SA 351 CF8M,SA 479 316L | |||

| 9 | Spring plate 2 pcs | 1.0718/Steel | 1.4404/316L |

| 10 | Adjusting screw | 1.4104 PTFE/Chrome steel PTFE | 1.4404 PTFE/316L PTFE |

| 11 | Ball | 1.3541/Hardened stainless steel | 1.4401/316 |

| 12 | Cap | 1.0718/12L13 | 1.4404/316L |

| 13 | Soft seal | EPDM (D) | EPDM (D) |

| 13 | Soft seal | Neoprene (K) | Neoprene (K) |

| 13 | Soft seal | Viton® (L) | Viton® (L) |

| AT4522, 4523 | ||||||||||||||||||||||

| DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow diameter | 12 | 18 | 18 | 18 | 23 | 29 | 37 | 46 | 60 | 74 | 92 | |||||||||||

| A (4) | 272 | 250 | 250 | 255 | 275 | 300 | 390 | 445 | 505 | 625 | 740 | |||||||||||

| B | 90 | 95 | 100 | 105 | 115 | 125 | 145 | 155 | 175 | 200 | 225 | |||||||||||

| C | 150 | 150 | 150 | 200 | 200 | 250 | 250 | 300 | 350 | 400 | 450 | |||||||||||

| Weight | 6,3 | 6,4 | 6,4 | 8,4 | 9,6 | 13 | 16 | 21,6 | 35,6 | 52,1 | 78,4 | |||||||||||

| Measurements in mm, weight in kg. (4)= with gastight lifting device | ||||||||||||||||||||||

| AT 4577, 4578 | ||||||||||||||||||

| DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow diameter | 12 | 18 | 18 | 18 | 23 | 29 | 37 | 46 | 60 | |||||||||

| A (4) | 272 | 250 | 250 | 255 | 275 | 300 | 390 | 445 | 505 | |||||||||

| B | 90 | 95 | 100 | 105 | 115 | 125 | 145 | 155 | 175 | |||||||||

| C | 150 | 150 | 150 | 200 | 200 | 250 | 250 | 300 | 350 | |||||||||

| Weight | 6,3 | 6,4 | 6,4 | 8,4 | 9,6 | 13 | 16 | 21,6 | 35,6 | |||||||||

| Measurements in mm, weight in kg. (2)= with gas tight cap (4)= with gas tight lifting device | ||||||||||||||||||

Spring loaded and directly acting safety valve with standard characteristics, with stainless steel bellows. The bellows can compensate for varying back-pressure up to around 35 % of the set pressure. In addition, the bellows protect the moving parts against dirt, corrosion and temperature. With lifting device for manual testing or with gas tight cap. If possible, a soft sealing disc should be used since it has better tightness and is easier to renovate.

| Steam/air/gases: | Max 10% at set pressure ≥ 3,0 bar | |

| Max 0,3 bar at set pressure < 3,0 bar | ||

| Liquids: | Max 20% at set pressure ≥ 3,0 bar | |

| Max 0,6 bar at set pressure < 3,0 bar | ||

If lower blowdown pressure is requested please contact Armatec | ||

| AT 4522/AT 4523 | AT 4577/AT 4578 | |||||||

| Set pressure | Temp. | Set pressure- | Temp. | |||||

| max. | -85°C to | max. | -270°C to | |||||

| DN | bar | +450°C | bar | +400°C | ||||

| 15 | 40 | 40 | ||||||

| 20 | 40 | 40 | ||||||

| 25 | 40 | 40 | ||||||

| 32 | 40 | 40 | ||||||

| 40 | 40 | 40 | ||||||

| 50 | 40 | 40 | ||||||

| 65 | 40 | 26 | ||||||

| 80 | 35 | 25 | ||||||

| 100 | 30 | 22 | ||||||

| 125 | 32 | - | ||||||

| 150 | 16 | - | ||||||

| Pressure and temperatures according to applied standards for each valve material. At temperatures above 200 oC the temperature has to be specified in the order, so that a high temperature spring is used. If other temperatures and pressures limits are requested please contact Armatec. | ||||||||

| Temperature range soft sealed safety valves; AT 4523 and 4578 | |

| O-ring | Neoprene (CR) K -40°C to +100°C, e.g. refrigants |

| Ethylene (EPDM) D -45°C to +150°C, e.g. hot water and low temperature steam | |

| Viton (FPM) L -20°C to +180°C, e.g. oil and air |

Sizing based on submitted data can be performed on request.

Please state: Fluid, density (for liquids), capacity/power, maximum temperature and set pressure

Bar implies bar gauge: bar(ö), bar(g), bar(e), atö or kg/cm2 if nothing else is stated.

Nm3/h implies "free" capacity air/gas (N=normal) and is equal with m3/h if other is not stated.

Coefficient of discharge steam/gases αd D/G

DN15 metal to metal: 0,62

DN15 soft sealed: 0,59

DN20: 0,29

DN25-150: 0,38

Coefficient of discharge liquids αd F

DN15 metal to metal: 0,48

DN15 soft sealed: 0,47

DN20: 0,19

DN25-150: 0,25

Flow diameter, Do see Dimension and weight.

| DN | 15 | 15 | 20 | 25+32 | 40 | 50 | ||||||||||||||||||||||||||||||

| Seat | Met. 12mm | Soft 12mm | 18mm | 18mm | 23mm | 29mm | ||||||||||||||||||||||||||||||

Pset | ||||||||||||||||||||||||||||||||||||

| bar | Steam | Air | Water | Steam | Air | Water | Steam | Air | Water | Steam | Air | Water | Steam | Air | Water | Steam | Air | Water | ||||||||||||||||||

| 0, 2 | 36 | 43 | 1678 | 35 | 41 | 1633 | 1 | 1 | 1500 | 32 | 38 | 1967 | 53 | 63 | 3211 | 84 | 99 | 5111 | ||||||||||||||||||

| 0, 5 | 57 | 70 | 2378 | 54 | 66 | 2333 | 32 | 39 | 2111 | 68 | 84 | 2789 | 111 | 137 | 4544 | 177 | 217 | 7233 | ||||||||||||||||||

| 1 | 81 | 102 | 3222 | 77 | 97 | 3156 | 72 | 90 | 2867 | 106 | 133 | 3767 | 173 | 218 | 6156 | 277 | 347 | 9789 | ||||||||||||||||||

| 2 | 128 | 163 | 4556 | 121 | 156 | 4467 | 133 | 170 | 4056 | 178 | 227 | 5333 | 290 | 370 | 8711 | 461 | 588 | 13889 | ||||||||||||||||||

| 3 | 172 | 221 | 5578 | 163 | 210 | 5467 | 184 | 237 | 4967 | 240 | 309 | 6533 | 392 | 504 | 10667 | 624 | 802 | 17000 | ||||||||||||||||||

| 4 | 214 | 278 | 6433 | 203 | 264 | 6300 | 233 | 301 | 5733 | 306 | 396 | 7544 | 499 | 646 | 12333 | 793 | 1026 | 19556 | ||||||||||||||||||

| 5 | 257 | 333 | 7200 | - | 317 | 7056 | 279 | 363 | 6411 | 366 | 476 | 5100 | 598 | 777 | 13778 | 950 | 1233 | 21889 | ||||||||||||||||||

| 6 | 299 | 390 | 7878 | - | 370 | 7722 | 326 | 424 | 7022 | 426 | 556 | 9233 | 696 | 908 | 15111 | 1106 | 1433 | 24000 | ||||||||||||||||||

| 7 | 341 | 447 | 8511 | - | 424 | 8344 | 371 | 486 | 7578 | 486 | 637 | 9978 | 793 | 1039 | 16333 | 1256 | 1644 | 25889 | ||||||||||||||||||

| 8 | 383 | 503 | 9100 | - | 478 | 8922 | 417 | 547 | 8111 | 546 | 717 | 10667 | 891 | 1167 | 17444 | 1411 | 1856 | 27667 | ||||||||||||||||||

| 9 | 426 | 560 | 9656 | - | 532 | 9467 | 462 | 609 | 8600 | 606 | 798 | 11333 | 989 | 1300 | 18444 | 1567 | 2067 | 29333 | ||||||||||||||||||

| 10 | 467 | 617 | 10178 | - | 586 | 9978 | 508 | 670 | 9067 | 666 | 878 | 11889 | 1087 | 1433 | 19444 | 1722 | 2278 | 31000 | ||||||||||||||||||

| 12 | 551 | 729 | 11111 | - | 692 | 10889 | 599 | 793 | 9922 | 784 | 1039 | 13111 | 1278 | 1689 | 21333 | 2033 | 2689 | 33889 | ||||||||||||||||||

| 14 | 634 | 842 | 12000 | - | 800 | 11778 | 690 | 916 | 10722 | 904 | 1189 | 14111 | 1467 | 1956 | 23000 | 2344 | 3111 | 36667 | ||||||||||||||||||

| 16 | 718 | 954 | 12889 | - | 907 | 12667 | 781 | 1039 | 11444 | 1023 | 1356 | 15111 | 1667 | 2211 | 24667 | 2656 | 3522 | 39111 | ||||||||||||||||||

| 18 | 802 | 1068 | 13667 | - | 1014 | 13444 | 872 | 1156 | 12111 | 1133 | 1511 | 16000 | 1856 | 2478 | 26111 | 2967 | 3944 | 41556 | ||||||||||||||||||

| 20 | 887 | 1178 | 14444 | - | 1122 | 14111 | 963 | 1278 | 12778 | 1256 | 1678 | 16889 | 2056 | 2744 | 27556 | 3278 | 4367 | 43778 | ||||||||||||||||||

| 22 | 971 | 1289 | 15111 | - | 1222 | 14778 | 1056 | 1400 | 13444 | 1378 | 1833 | 17667 | 2256 | 3000 | 28889 | 3589 | 4778 | 45889 | ||||||||||||||||||

| 24 | 1056 | 1400 | 15778 | - | 1333 | 15444 | 1144 | 1522 | 14000 | 1500 | 2000 | 18444 | 2444 | 3267 | 30111 | 3900 | 5200 | 48000 | ||||||||||||||||||

| 26 | 1133 | 1511 | 16444 | - | 1433 | 16111 | 1233 | 1644 | 14667 | 1622 | 2156 | 19222 | 2644 | 3533 | 31444 | 4211 | 5611 | 49889 | ||||||||||||||||||

| 28 | 1222 | 1622 | 17000 | - | 1544 | 16667 | 1322 | 1767 | 15111 | 1744 | 2322 | 20000 | 2844 | 3789 | 32556 | 4522 | 6033 | 51778 | ||||||||||||||||||

| 30 | 1300 | 1744 | 17667 | - | 1656 | 17333 | 1422 | 1889 | 15667 | 1867 | 2478 | 20667 | 3044 | 4056 | 33667 | 4844 | 6456 | 53556 | ||||||||||||||||||

| 32 | 1389 | 1856 | 18222 | - | 1767 | 17889 | 1511 | 2011 | 16222 | 1989 | 2644 | 21333 | 3244 | 4322 | 34778 | 5156 | 6867 | 55333 | ||||||||||||||||||

| 34 | - | 1967 | 18778 | - | 1867 | 18444 | - | 2133 | 16667 | - | 2800 | 22000 | - | 4578 | 35889 | - | 7289 | 57111 | ||||||||||||||||||

| 36 | - | 2078 | 19333 | - | 1978 | 19000 | - | 2267 | 17222 | - | 2967 | 22667 | - | 4844 | 36889 | - | 7700 | 58778 | ||||||||||||||||||

| 38 | - | 2189 | 19889 | - | 2078 | 19444 | - | 2389 | 17667 | - | 3122 | 23222 | - | 5111 | 38000 | - | 8122 | 60333 | ||||||||||||||||||

| 40 | - | 2300 | 20333 | - | 2189 | 19889 | - | 2511 | 18111 | - | 3289 | 23889 | - | 5367 | 38889 | - | 8544 | 61889 | ||||||||||||||||||

| Pset = set pressure According to applied standards the value above should be multiplied with the safety factor 0,9. Saturated steam in kg/h. Air in Nm3/h (free air) at 0ºC and atmospheric pressure 1013 mbar(a). Water in kg/h at 20ºC. Capacities are given for an overpressure of 10% of set pressure. Contact Armatec for sizing with other fluids etc. | ||||||||||||||||||||||||||||||||||||

| DN | 65 | 80 | 100 | 125 | 150 | |||||||||||||||||||||||||

| Seat | 37mm | 46mm | 60mm | 74mm | 92mm | |||||||||||||||||||||||||

| Pset | ||||||||||||||||||||||||||||||

| bar | Steam | Air | Water | Steam | Air | Water | Steam | Air | Water | Steam | Air | Water | Steam | Air | Water | |||||||||||||||

| 0,2 | 137 | 162 | 8322 | 211 | 250 | 12889 | 359 | 426 | 21889 | 547 | 647 | 33333 | 844 | 1001 | 51444 | |||||||||||||||

| 0,5 | 288 | 353 | 11778 | 446 | 546 | 18222 | 758 | 929 | 30889 | 1144 | 1411 | 47111 | 1778 | 2178 | 72778 | |||||||||||||||

| 1 | 450 | 564 | 15889 | 694 | 873 | 24667 | 1178 | 1478 | 41889 | 1789 | 2256 | 63778 | 2778 | 3489 | 98556 | |||||||||||||||

| 2 | 751 | 957 | 22556 | 1156 | 1478 | 34778 | 1967 | 2511 | 59222 | 3000 | 3822 | 90111 | 4644 | 5911 | 138889 | |||||||||||||||

| 3 | 1016 | 1300 | 27556 | 1567 | 2011 | 42667 | 2667 | 3422 | 72556 | 4056 | 5211 | 110333 | 6278 | 8067 | 171111 | |||||||||||||||

| 4 | 1289 | 1667 | 31889 | 1989 | 2578 | 49222 | 3389 | 3422 | 83778 | 5156 | 6667 | 127778 | 7978 | 10311 | 196667 | |||||||||||||||

| 5 | 1544 | 2000 | 35667 | 2389 | 3100 | 55111 | 4056 | 4389 | 93667 | 6178 | 8033 | 142222 | 9556 | 12333 | 220000 | |||||||||||||||

| 6 | 1800 | 2344 | 39000 | 2778 | 3622 | 60333 | 4733 | 5278 | 102667 | 7200 | 9389 | 155556 | 11111 | 14444 | 241111 | |||||||||||||||

| 7 | 2044 | 2689 | 42111 | 3167 | 4156 | 65111 | 5400 | 6178 | 110889 | 8211 | 10756 | 168889 | 12667 | 16556 | 261111 | |||||||||||||||

| 8 | 2300 | 3022 | 45111 | 3556 | 4678 | 69667 | 6056 | 7067 | 118889 | 9222 | 12111 | 180000 | 14222 | 18667 | 278889 | |||||||||||||||

| 9 | 2556 | 3367 | 47778 | 3944 | 5200 | 73889 | 6722 | 7967 | 125556 | 10233 | 13444 | 191111 | 15778 | 20778 | 295556 | |||||||||||||||

| 10 | 2811 | 3700 | 50333 | 4344 | 5733 | 77889 | 7389 | 8856 | 132222 | 11222 | 14778 | 201111 | 17333 | 22889 | 311111 | |||||||||||||||

| 12 | 3311 | 4389 | 55222 | 5122 | 6778 | 85333 | 8711 | 9744 | 145556 | 13222 | 17556 | 221111 | 20444 | 27111 | 341111 | |||||||||||||||

| 14 | 4322 | 5067 | 59667 | 5900 | 7833 | 92111 | 10044 | 11444 | 156667 | 15222 | 20222 | 238889 | 23556 | 31333 | 368889 | |||||||||||||||

| 16 | 4822 | 5744 | 63778 | 6678 | 8878 | 98556 | 11333 | 13222 | 167778 | 17222 | 23000 | 254444 | 26667 | 35444 | 394444 | |||||||||||||||

| 18 | 5333 | 6422 | 67556 | 7456 | 9933 | 104444 | 12667 | 15111 | 177778 | 19222 | 25667 | 270000 | 29889 | 40222 | 417778 | |||||||||||||||

| 20 | 5844 | 7100 | 71222 | 8244 | 10989 | 110111 | 14000 | 16889 | 187778 | 21333 | 28333 | 285556 | - | - | - | |||||||||||||||

| 22 | 6344 | 7789 | 74778 | 9033 | 12000 | 115556 | 15333 | 18667 | 196667 | 23333 | 31111 | 298889 | - | - | - | |||||||||||||||

| 24 | 6856 | 8467 | 78000 | 9811 | 13000 | 121111 | 16667 | 20444 | 205556 | 25333 | 33778 | 312222 | - | - | - | |||||||||||||||

| 26 | 7367 | 9144 | 81222 | 10600 | 14111 | 125556 | 18000 | 22222 | 213333 | - | - | - | - | - | - | |||||||||||||||

| 38 | 7889 | 9822 | 84333 | 11333 | 15111 | 130000 | 19333 | 24000 | 222222 | - | - | - | - | - | - | |||||||||||||||

| 30 | 8400 | 10500 | 87222 | 12111 | 16222 | 134444 | 20667 | 25778 | 230000 | - | - | - | - | - | - | |||||||||||||||

| 32 | - | 11111 | 90111 | 12889 | 17222 | 138889 | 22000 | 29333 | 236667 | - | - | - | - | - | - | |||||||||||||||

| 34 | - | 11778 | 92889 | - | 18333 | 143333 | - | 31667 | 244444 | - | - | - | - | - | - | |||||||||||||||

| 36 | - | - | - | - | 19667 | 147778 | - | 33444 | 251111 | - | - | - | - | - | - | |||||||||||||||

| 38 | - | - | - | - | 20667 | 152222 | - | - | - | - | - | - | - | - | - | |||||||||||||||

| 40 | - | - | - | - | 21778 | 155556 | - | - | - | - | - | - | - | - | - | |||||||||||||||

| Pset = set pressure According to applied standards the value above should be multiplied with the safety factor 0,9. Saturated steam in kg/h. Air in Nm3/h (free air) at 0ºC and atmospheric pressure 1013 mbar(a). Water in kg/h at 20ºC. Capacities are given for an overpressure of 10% of set pressure. Contact Armatec for sizing with other fluids etc. | ||||||||||||||||||||||||||||||

| Connection | Flanges drilled acc. to | |||

|---|---|---|---|---|

| AT 4522/AT 4523 | AT 4577/AT 4578 | |||

| Inlet | DIN EN 1092-1, PN40 | DIN EN 1092-1, PN40 | ||

| Outlet | DIN EN 1092-1, PN40 | DIN EN 1092-1, PN40 | ||

See separate installation instruction. The valve should be mounted with the bonnet in vertical position. The stainless steel bellows has a connection for drainage piping or for leak detection piping (which can show if the bellows are broken). Mounted protection plug is removed and replaced on site with appropriate device. | ||||

| Metal seated safety valve with stainless steel bellow | |||

| Example: AT 4522-4-5,0-25 | |||

| AT 4522 | -4 | -5,0 | -25 |

|---|---|---|---|

| Fig. no | design | Set pressure (barg) | DN |

| AT 4522=steel | -2=gas tight cap | ||

| AT 4577=stainless steel | -4=gas tight lifting device |

| Soft seated safety valve with stainless steel bellow | ||||

| Exempel: AT 4523D4-5,0-25 | ||||

| AT 4523 | D | 4 | -5,0 | -25 |

|---|---|---|---|---|

| Fig.no. | O-ring | Design | Set pressure (barg) | DN |

| AT 4523=steel | D=EPDM | 2=gas tight cap | ||

| AT 4578=stainless steel | L=Viton | 4=gas tight lifting device | ||

| K=Neoprene | ||||

| N=Nitrile |