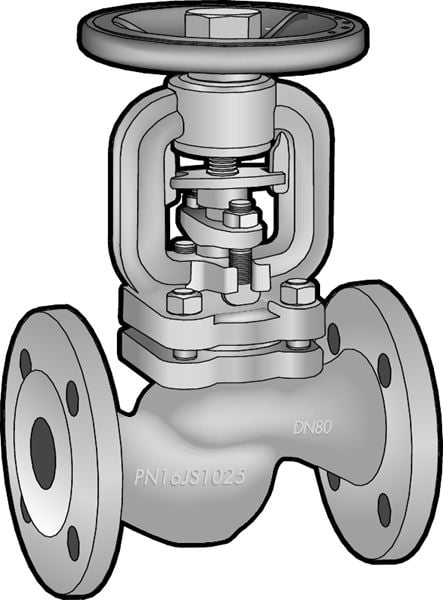

The globe valve is made of steel with flanges, PN 40, with bellows that prevents the media from coming in contact with the stuffing box.

Maintenance-free, external spindle thread, a display device that shows open/closed mode and a non-steering wheel. A shut-off valve for non-aggressive fluids, gas and steam.

| Dimension range | DN 15 to DN 200 |

|---|---|

| PN | 40 |

| Temperature range | -10 °C to +400 ºC |

| Material | Steel |

| Article number | Amount |

|---|---|

| AT 1050D15 | |

| AT 1050D20 | |

| AT 1050D25 | |

| AT 1050D32 | |

| AT 1050D40 | |

| AT 1050D50 | |

| AT 1050D65 | |

| AT 1050D80 | |

| AT 1050D100 | |

| AT 1050D125 | |

| AT 1050D150 | |

| AT 1050D200 |

| Dimension range | PN | Temperature range | Material |

|---|---|---|---|

| DN 15-250 | 40 | -10 °C to 400 ºC | Steel |

As a shut-off valve for non-aggressive fluids, gases and steam.

Pressurized parts are manufactured in a foundry, which is generally approved by all recognized classification authorities.

Certificate SS-EN10204, type 2.2 and 3.1, as well as by most classification authorities (type of certificate is to be stated upon ordering). Testing carried out in accordance with DIN EN 12266.

CE-marking

The valves meet the requirements in AFS 2016:1 and 2014/68/EU (Pressure Equipment Directive).

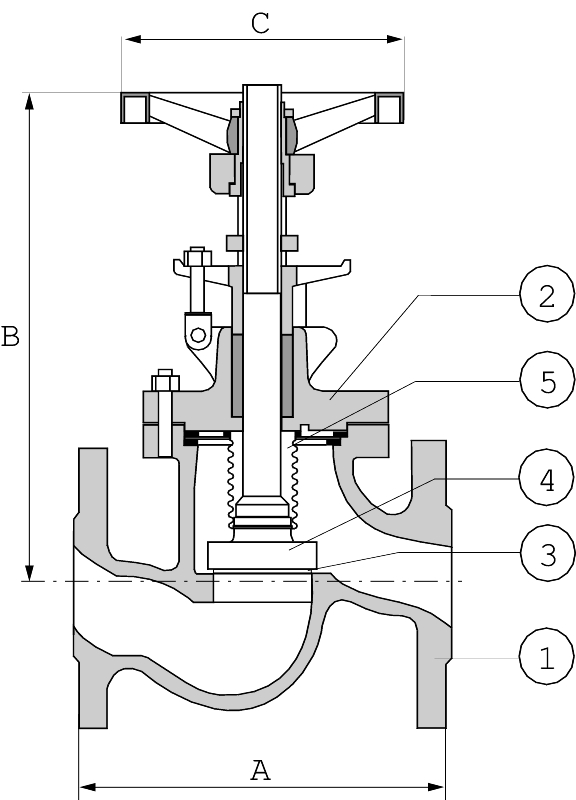

| Pos | Component | Material |

|---|---|---|

| 1 | Body | Steel 1.0619 |

| 2 | Bonnet | Steel 1.0619 |

| 3 | Seat | Stainless steel 1.4021 |

| 4 | Cone | Stainless steel 1.4021 |

| 5 | Bellow | Stainless steel 1.4301 |

| DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 130 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | ||||||||||||

| B | 208 | 208 | 217 | 215 | 235 | 235 | 252 | 270 | 347 | 380 | 420 | 570 | ||||||||||||

| C | 120 | 140 | 140 | 140 | 160 | 160 | 180 | 200 | 250 | 250 | 360 | 450 | ||||||||||||

| Weight | 4,4 | 4,9 | 5,8 | 7,4 | 9,4 | 12,2 | 17,3 | 23,4 | 40,4 | 58 | 83,8 | 133 | ||||||||||||

| Dimension in mm, weight in kg | ||||||||||||||||||||||||

With bellows that prevents the media from coming in contact with the stuffing box. This eliminates the risk of leakage from the stuffing box.

- Maintenance-free

- External stem thread

- Position indicator, open/closed

- Non-rising handwheel

| Working pressure max. bar | Working temperature. max. °C |

|---|---|

| 35 | 200 |

| 28 | 300 |

| 21 | 400 |

| DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Kvs | 4,7 | 7,4 | 11,2 | 18,3 | 29,3 | 44,2 | 73,2 | 112,2 | 173,0 | 290,0 | 412,0 | 702,0 | 1020,0 |

Difference Pressure

For differential pressure greater than stated below, a bypass should be used in order to facilitate maneuvering and obtain a good seat tightness.

| DN | 125 | 150 |

|---|---|---|

| ∆p bar | 24 | 17 |

| Flanges acc. to |

|---|

| DIN EN 1092-1 |

| Example: AT 1050D50 | |||||

| AT 1050D | 50 | ||||

|---|---|---|---|---|---|

| Fig. nr. | DN | ||||

| RSK-number, see the RSK-register. | |||||