High quality tight butterfly valve, SEMI-LUG performance with a fixed vulcanized rubber lining in the body. Also suitable for vacuum and as a end valve with lever, worm gear or actuators. With a long neck for insulation.

| Dimension range | DN50 to DN2200 |

|---|---|

| PN | 16/10 |

| Temperature range | -20ºC to 110ºC |

| Material | Cast iron |

| Dimension range | PN | Temperature range | Material |

|---|---|---|---|

DN 50-1400 | 10/16 | -20 ºC to +200 ºC | Cast iron |

Soft seal , butterfly valve for shut-off and control of hot and cold water, air and other neutral gases. For example, tap water, wastewater, sea water, oils and glycol mixtures. See also: "Selection of Butterfly Valves".

NBR-lining: 0°C to +90°C Hydrocarbon compounds with up to 30% aromatics at +20 ° C, water, powder, air and neutral gases.

EPDM-lining: -20°C to +110°C Tap water, some alcohols (max 30%), certain diluted inorganic acids.

EPDM Hightemp: -20°C to +130°C Hot or cold water with extended temperature range.

Viton-lining: 0°C to +200°C Hydrocarbon compounds, oils and hot air.

The valves are corrossion protection painted according to EN12944 class C3 as a standard. Other classes on demand.

PSB.2 Butterfly valve

Butterfly valve AT 231x with body of gray iron, fixed vulcanized rubber liner of NBR/EPDM and disc of stainless steel.

Butterfly valve AT 2314 with body of gray iron, fixed vulcanized rubber liner of NBR and disc of alubronze.

Butterfly valve AT 2319 with body of nodular iron, fixed vulcanized rubber liner of Viton and disc of stainless steel.

With long stem neck (up to DN200) for insulation and mounting wholes for one sided flange mounting.

AT 231xS with standard shaft up to DN150,

AT 231xV with standard gear from DN200.

Testing is performed according to SS-ISO 5208 edition 2, leakage rate A, applies to the valve type.

Certificate SS-EN 10204 2.2 from most of the classification authorities can be delivered.

Certificate SS-EN 10204 3.1 can be supplied on special order.

Type of certificate has to be specified upon ordering.

End valve DN 50–200 max. 10 bar, DN 250–300 max. 6 bar.

CE-marking.

AT 2310-2319 are in compliance with PED 2014/68/EU category 1 as a standard.

Other categories are available on request.

| AT 2310 | AT 2311 | AT 2312 | AT 2313 | AT 2314 | AT 2319 | ||

|---|---|---|---|---|---|---|---|

| 1 | Body | JL1040 | JL1040 | JL1040 | JL1040 | JL1040 | JS1030 |

| 2 | Disk | ||||||

| (DN 50-600) | 1.4057 | 1.4057 | 1.4462 Duplex | 1.4462 Duplex | G-CuAl10Ni | 1.4462 Duplex | |

| (DN 700-1600) | 1.4057 | 1.4057 | 1.4517 Duplex | 1.4517 Duplex | G-CuAl10Ni | 1.4517 Duplex | |

| 3 | Shafts | 1.4057 | 1.4057 | 1.4462 | 1.4462 | CuAl10Ni5Fe4 | 1.4462 |

| 4 | Linig | NBR | EPDM | NBR | EPDM | NBR | Viton® |

| 5 | Bushing | Steel-PTFE | Steel-PTFE | Steel-PTFE | Steel-PTFE | Steel-PTFE | Steel-PTFE |

| seal ring | Copper | Copper | Copper | Copper | Copper | Copper | |

| Plugg | Steel | Steel | Steel | Steel | Steel | Steel | |

| 6 | Standard corrosion protection (SS-EN 12944) | C3 | C3 | C3 | C3 | C3 | C3 |

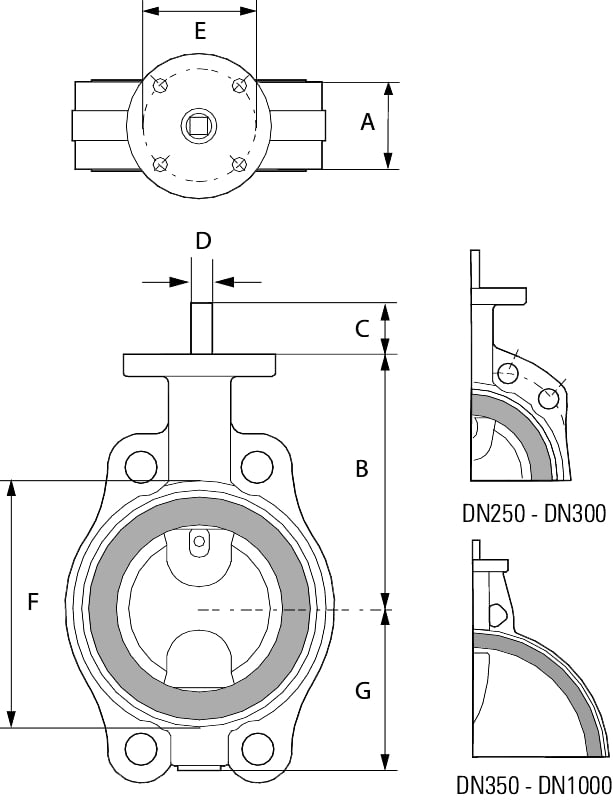

| DN | A | B | B* | C | D | E | F | G | Weight | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 50 | 43 | 118 | 152 | 34 | 10 | 70 | 100 | 63 | 3,1 | |||||||||

| 65 | 46 | 126 | 160 | 34 | 10 | 70 | 115 | 71 | 3,9 | |||||||||

| 80 | 46 | 133 | 167 | 34 | 10 | 70 | 130 | 78 | 4,2 | |||||||||

| 100 | 52 | 147 | 189 | 34 | 12 | 70 | 150 | 96 | 5,5 | |||||||||

| 125 | 56 | 160 | 202 | 34 | 12 | 70 | 182 | 109 | 7 | |||||||||

| 150 | 56 | 180 | 224 | 34 | 16 | 70 | 210 | 133 | 10 | |||||||||

| 200 | 60 | 204 | 248 | 34 | 16 | 70 | 262 | 158 | 14 | |||||||||

| 250 | 68 | 245 | 45 | 24 | 102 | 315 | 194 | 22 | ||||||||||

| 300 | 78 | 270 | 45 | 24 | 102 | 371 | 219 | 32 | ||||||||||

| 350 | 78 | 315 | 45 | 24 | 102 | 405 | 256 | 40 | ||||||||||

| 400 | 102 | 363 | 50 | 30 | 140 | 470 | 308 | 75 | ||||||||||

| 450 | 114 | 388 | 50 | 30 | 140 | 522 | 334 | 90 | ||||||||||

| 500 | 127 | 413 | 50 | 30 | 140 | 576 | 360 | 120 | ||||||||||

| 600 | 154 | 510 | 50 | 40 | 140 | 672 | 426 | 180 | ||||||||||

| 700 | 165 | 560 | 60 | 46 | 165 | 776 | 480 | 295 | ||||||||||

| 800 | 190 | 610 | 60 | 46 | 165 | 880 | 525 | 345 | ||||||||||

| 900 | 203 | 690 | 70 | 60 | 254 | 980 | 635 | 475 | ||||||||||

| 1000 | 216 | 740 | 70 | 60 | 254 | 1085 | 685 | 635 | ||||||||||

B* AT 2310-11 with long steam neck for insulation. DN 50-200. | ||||||||||||||||||

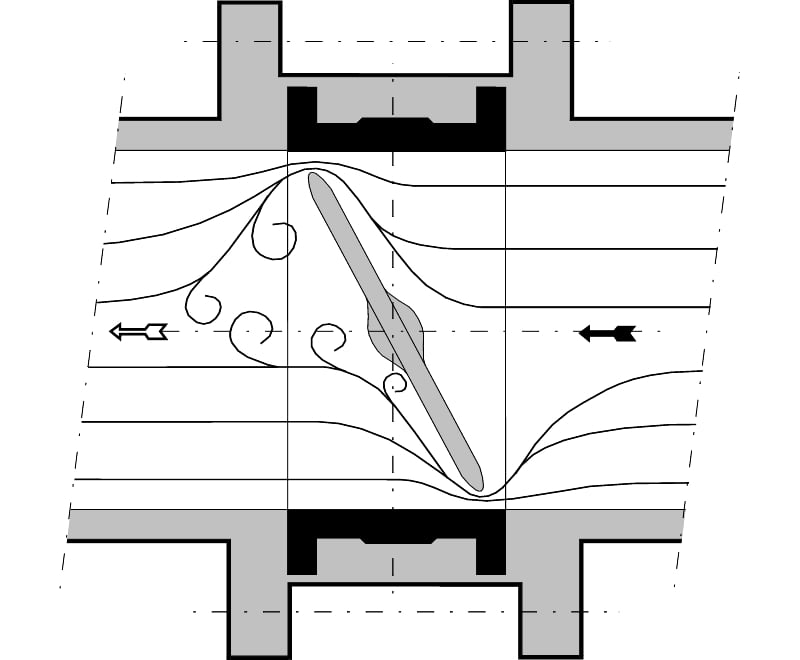

Fully tight, maintenance-free butterfly valve with centrically placed disc , split stem, one-piece body with fixed vulcanized rubber lining, eliminating risk of contact corrosion and protecting body internally against corrosion and also serving as flange packing. The manufacturing process ensures excellent seal and increased longevity because the abrasion of the liner is eliminated. Disc profile is crucial for achieving good flow characteristics which ultimately leads to energy losses are minimized. The valve is sealed regardless of flow direction.

Body with SEMI-LUG mounting wholes for one sided mounting.

AT 2310 and AT 2311 are equipped with mounting holes up to DN 300. Porting pattern acc. to PN16 up to DN 200 and PN10 for DN250-300.

AT 2312, AT 2313 and AT 2314 are equipped with mounting holes up to DN 200.

Due to this design, the valve will keep its seal function even with one sided flange mounting, as an example end valve.

Disc and shaft are connected by one or more strong conical pins.

Butterfly valve AT 2310-11 DN 50–200 is delivered with long stem neck as standard for insulation.

Face to face dimension acc. to SS-EN 558.

Top flange acc. to ISO 5211.

Standard corrosion class C3 acc. to ISO 12944.

When the installation is done outdoors without rain cover, class C4 is recommended.

| Pressure and temperature | |||

| Fig. No | DN | Working pressure | Working temperature. |

|---|---|---|---|

| Max bar | Max °C | ||

| AT 2310 | 50-200 | 16* | 90 |

| AT 2311 | 50-200 | 16* | 120 |

| AT 2313 | 50-300 | 16* | 120 |

| AT 2314/2312 | 50-300 | 16* | 90 |

| AT 2310 | 250-1600 | 10** | 90 |

| AT 2311 | 250-1600 | 10** | 120 |

| AT 2313 | 350-1600 | 10 | 120 |

| AT 2312/2314 | 350-1600 | 10 | 90 |

| AT 2319 | 50-1600 | 10** | 200 |

| * End of the line valve DN 50-200 Max. 10 bar (e). | |||

| **End of the line valve DN 250-300 Max. 6 bar (e). |

| KVs-value and Torque | ||||||||||||||

| DN | Kvs-value | Torque (Nm), Differential pressure (bar) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AT 2310/2311 | AT 2312/2313 | AT 2314 | 2,5 | 6 | 10 | 16 | ||||||||

| 50 | 95 | 95 | 95 | 9 | 10 | 10 | 11 | |||||||

| 65 | 231 | 231 | 231 | 13 | 13 | 14 | 15 | |||||||

| 80 | 491 | 491 | 491 | 17 | 18 | 19 | 21 | |||||||

| 100 | 690 | 690 | 690 | 28 | 30 | 32 | 36 | |||||||

| 125 | 1450 | 1450 | 1450 | 39 | 42 | 46 | 52 | |||||||

| 150 | 1945 | 1945 | 1945 | 60 | 67 | 75 | 86 | |||||||

| 200 | 4095 | 4095 | 4095 | 120 | 130 | 140 | 160 | |||||||

| 250 | 6085 | 6085 | 4260 | 300 | 320 | 350 | 400 | |||||||

| 300 | 9570 | 9570 | 6360 | 420 | 450 | 490 | 560 | |||||||

| 350 | 13500 | 13500 | 8975 | 310 | 360 | 410 | 660 | |||||||

| 400 | 16350 | 16350 | 10130 | 460 | 540 | 640 | 1020 | |||||||

| 450 | 21550 | 21550 | 12730 | 630 | 740 | 850 | 1400 | |||||||

| 500 | 17000 | 17000 | 17000 | 840 | 970 | 1120 | 1800 | |||||||

| 600 | 24810 | 24810 | 24810 | 910 | 1100 | 1900 | 3100 | |||||||

| 700 | 34470 | 34470 | 34470 | 1500 | 1900 | 3200 | 5200 | |||||||

| 800 | 45540 | 45540 | 45540 | 2100 | 2600 | 4400 | 7000 | |||||||

| 900 | 58290 | 58290 | 58290 | 2900 | 3800 | 6400 | 10200 | |||||||

| 1000 | 73510 | 73510 | 73510 | 3800 | 4900 | 8100 | 13000 | |||||||

| 1200 | 108400 | 108400 | 108400 | 5900 | 7900 | 13000 | 21000 | |||||||

| 1400 | 151400 | 151400 | 151400 | 9000 | 12000 | 20000 | 32000 | |||||||

| 1600 | 203200 | - | 203200 | 12000 | 17000 | 29000 | 46000 | |||||||

| The torque applies for standard valves: - Temperature 0≤80 °C - Liquids - Gases always at diff.pressure 6 bar or specially finished disc PN6 - Viton®-lining always at Dp 10 bar - Manoeuvering min. 10 times/year. | ||||||||||||||

| Kvs-value | ||||||||||||||

| Opening angle° | ||||||||||||||

| DN | 20 | 40 | 50 | 60 | 70 | 80 | 90 | |||||||

| 50 | 3 | 13 | 24 | 44 | 72 | 90 | 95 | |||||||

| 65 | 7 | 22 | 44 | 79 | 136 | 212 | 231 | |||||||

| 80 | 15 | 42 | 82 | 135 | 231 | 378 | 491 | |||||||

| 100 | 21 | 82 | 148 | 246 | 414 | 660 | 690 | |||||||

| 125 | 44 | 125 | 232 | 370 | 650 | 1110 | 1450 | |||||||

| 150 | 58 | 225 | 383 | 592 | 1016 | 1691 | 1945 | |||||||

200 | 123 | 352 | 599 | 967 | 1615 | 2878 | 4095 | |||||||

| 250 | 183 | 626 | 1151 | 1939 | 3289 | 5154 | 6085 | |||||||

| 300 | 287 | 984 | 1809 | 3050 | 5172 | 8105 | 9570 | |||||||

| 350 | 405 | 1388 | 2553 | 4303 | 7296 | 11434 | 13500 | |||||||

| 400 | 491 | 1681 | 3091 | 5211 | 8837 | 13848 | 16350 | |||||||

| 450 | 647 | 2216 | 4075 | 6868 | 11647 | 18252 | 21550 | |||||||

| Applies for AT2310/2311/2312/2313/2319 DN50-450 and AT2314 DN50-200 | ||||||||||||||

| Kvs-value | ||||||||||||||||||||||

| Opening angle° | ||||||||||||||||||||||

| DN | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | ||||||||||||||

| 250 | 171 | 299 | 554 | 938 | 1493 | 2474 | 3625 | 4265 | ||||||||||||||

| 300 | 254 | 445 | 763 | 1272 | 2099 | 3434 | 5533 | 6360 | ||||||||||||||

| 350 | 269 | 359 | 718 | 1167 | 1885 | 3141 | 5565 | 8975 | ||||||||||||||

| 400 | 405 | 717 | 1271 | 2222 | 3876 | 5774 | 8786 | 10130 | ||||||||||||||

| 450 | 509 | 810 | 1478 | 2497 | 4211 | 6716 | 10380 | 12730 | ||||||||||||||

| 500 | 680 | 1069 | 1943 | 3283 | 5452 | 8730 | 13677 | 17000 | ||||||||||||||

600 | 992 | 1560 | 2836 | 4791 | 7956 | 12741 | 19961 | 24810 | ||||||||||||||

| 700 | 1379 | 2167 | 3941 | 6656 | 11054 | 17701 | 27733 | 34470 | ||||||||||||||

| 800 | 1822 | 2863 | 5206 | 8794 | 14604 | 23386 | 36639 | 45540 | ||||||||||||||

| 900 | 2332 | 3665 | 6664 | 11256 | 18693 | 29933 | 46897 | 58290 | ||||||||||||||

| 1000 | 2940 | 4622 | 8404 | 14195 | 23574 | 37749 | 59142 | 73510 | ||||||||||||||

| 1100 | 3718 | 5844 | 10625 | 17947 | 29804 | 47727 | 74775 | 92940 | ||||||||||||||

| 1200 | 4336 | 6816 | 12392 | 20933 | 34762 | 55666 | 87213 | 108400 | ||||||||||||||

| 1400 | 6056 | 9519 | 17308 | 29237 | 48552 | 77748 | 121808 | 151400 | ||||||||||||||

| 1500 | 7044 | 11072 | 20132 | 34006 | 56473 | 90432 | 14681 | 176100 | ||||||||||||||

| 1600 | 8128 | 12776 | 23230 | 39240 | 65163 | 104348 | 163484 | 203200 | ||||||||||||||

| Applies for AT3210/2311/2312/2313/2319 DN500-1400 and AT2314 DN250-500 | ||||||||||||||||||||||

- Body of nodular iron

- Body with monoflange for end of line mounting DN250-1000

- Disc of nodular iron – epoxy coated

- Polished disc Ra 0,1

- Maschined disc PN 6 (undercut disc)

- Rubber-lining by EPDM special (-30°C to +120°C)

- Rubber-lining by FPM (-0°C to +200°C)

- Rubber-lining by NBR for natural gases according to DVGW-gas

- Surface finish, corrosion class C4, C5

- Alternative pressure class

- Extended stem in different performances

- Flanged valves, see series AT 2340

- Hand manoeuvring

The valves are delivered as standard with lever for DN 50–150 (AT 2390) or with worm gear (AT 2394) in all DN. or with worm gear AT 2394SPR with internal limit switches.

Accessories

AT 2390R blockable and lockable fine-slip with 20 positions, for lever

AT 2390L lockable plate with 10 positions, for lever

AT 2390KONT plate with 2 mechanical Honeywell limit switches, for lever

AT 2395 limit position open/closed for worm gear,

Proxymatly sensors erected on worm gear, type of sensors to be stated in the order. Lock chain mounted on the worm gear.

- Automatic manoeuvering

The valves can be supplied with AT actuators program adapted for compact direct mounting, for pneumatic, hydraulic or electrical operation.

| DN | Flanges according to | DN | Max torque Nm |

|---|---|---|---|

| 50-200 | SS-EN 1092 PN16 | 50-125 | 100 |

| 250-300 | SS-EN 1092 PN10/16 | 150-300 | 250 |

| 350-1600 | SS-EN 1092 PN10 |

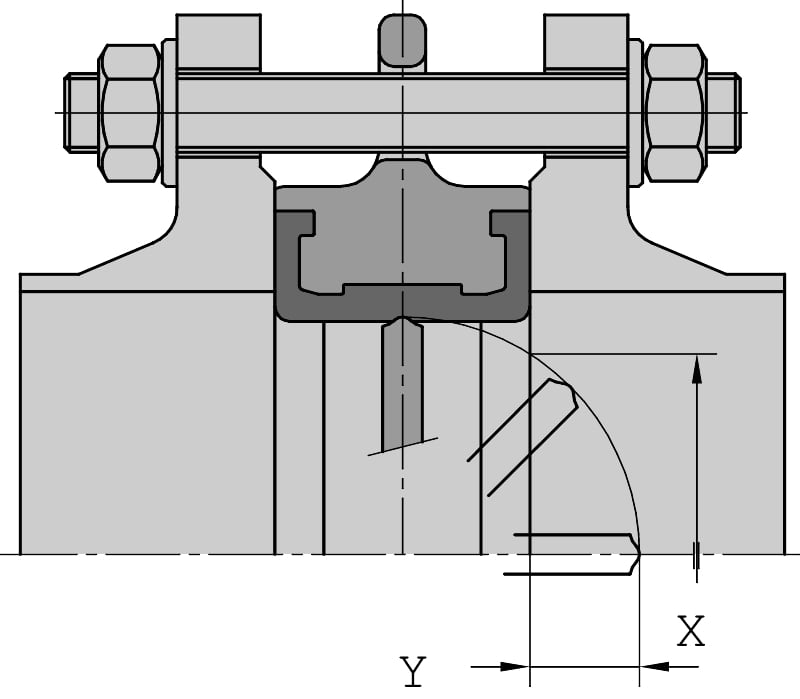

| Disc placement in the system | ||

| DN | X | Y |

|---|---|---|

| 50 | 26 | 3,5 |

| 65 | 46 | 9,5 |

| 80 | 66 | 17 |

| 100 | 86 | 24 |

| 125 | 112 | 34,5 |

| 150 | 140 | 47 |

| 200 | 191 | 70 |

| 250 | 241 | 92 |

| 300 | 290 | 114 |

| 350 | 327 | 130 |

| 400 | 373 | 142 |

| 450 | 421 | 161 |

| 500 | 470 | 180 |

| Example: AT 2310V200-1014 | |||||

| Butterfly valve, NBR lining, stainless disc with worm gear and extra surface coating C4 | |||||

| Valve | Lining | Manoeuvring | DN | Flange | Surface coating |

|---|---|---|---|---|---|

| 231X | 0= NBR/stainless steel | - = Free shaft end | 200= DN | PN10 | 1014= C4 |

| 1= EPDM/stainless steel | S = warm gear | PN16 | 1015= C5 | ||

| 2= NBR/acidproof steel | V= lever | ||||

| 3= EPDM/acidproof steel | |||||

| 4= NBR/alu-bronze | |||||

| 9= Viton®/acidproof steel |