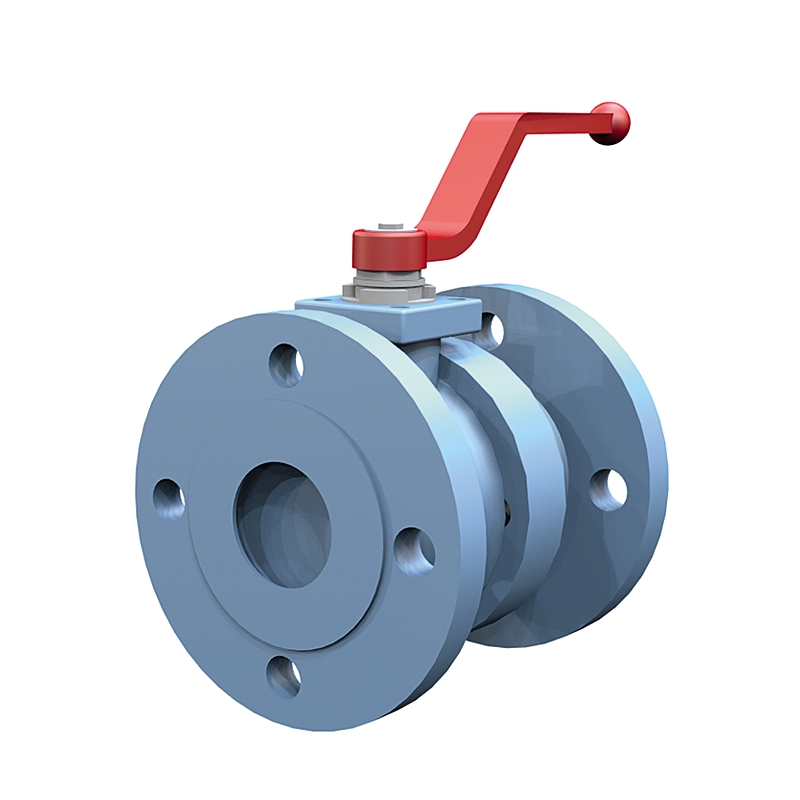

Ball valve in stainless steel or carbon steel with flanges and mounting flange for actuators. Suitable for automatization.

| Dimension range | DN 15 to 300 |

|---|---|

| PN | 16/40 |

| Temperature range | -50ºC to + 200ºC |

| Material | Stainless steel |

| Article number | Amount |

|---|---|

| AT 3582-15 | |

| AT 3582-20 | |

| AT 3582-25 | |

| AT 3582-32 | |

| AT 3582-40 | |

| AT 3582-50 | |

| AT 3582-65 | |

| AT 3582-80 | |

| AT 3582-100 | |

| AT 3582-125 | |

| AT 3582-150 | |

| AT 3582-200 | |

| AT 3582-250 | |

| AT 3582-300 | |

| AT 3585HT15 | |

| AT 3585HT20 | |

| AT 3585HT25 | |

| AT 3585HT32 | |

| AT 3585HT40 | |

| AT 3585HT50 | |

| AT 3585HT65 | |

| AT 3585HT80 | |

| AT 3585HT100 | |

| AT 3585HT125 | |

| AT 3585HT150 | |

| AT 3585HT200 | |

| AT 3585HT250 | |

| AT 3585HT300 |

| Dimension range | PN | Temperature range | Material |

|---|---|---|---|

DN 15-300 | 16-40 | -50ºC to +200ºC | Stainless steel |

| -20ºC till + 200ºC | Steel |

As shut-off valve mainly for:

- Acids and saline solutions

- Gas and steam

- Warm and cold water

| Valve of stainless steel AT 3582 | Valve of steel AT 3585 |

| Acids and saline solutions | Warm and cold water, compressed air |

| Solvents and alcohols | Saturated steam max 6 bar (e) |

| LPG, natural gases and petroleum products | LPG, natural gases and petroleum products |

Testing is carried out according to ISO 5208. Leakage class A applies to this type of valve. The valve is approved according to TA-Luft. Certificate according to EN 10204, type 2.2 and 3.1, has to be specified when ordering.

CE-marking

The valves meets the requirements of the PED, AFS 2016:1, the directive for pressure devices, according to category III, fluid group 1 and 2. Dimensions up to DN 25 fulfills § 8 of the PED, AFS 2016:1.

| Component | AT 3582 | AT3585 | |||

|---|---|---|---|---|---|

| 1 | Body | Stainless steel 1.4408 | Steel 1.0619 | ||

| 2 | Ball | Stainless steel 1.4408 | DN 15-32 | Stainless steel 1.4408 | DN 15-32 |

| Stainless steel 1.4401 | DN 40-300 | Stainless steel 1.4401 | DN 40-300 | ||

| 3 | Seat ring | PTFE | PTFE | ||

| 4 | Stem | Stainless steel 1.4408 | Stainless steel 1.4408 | ||

| 5 | Stem gasket | PTFE | PTFE |

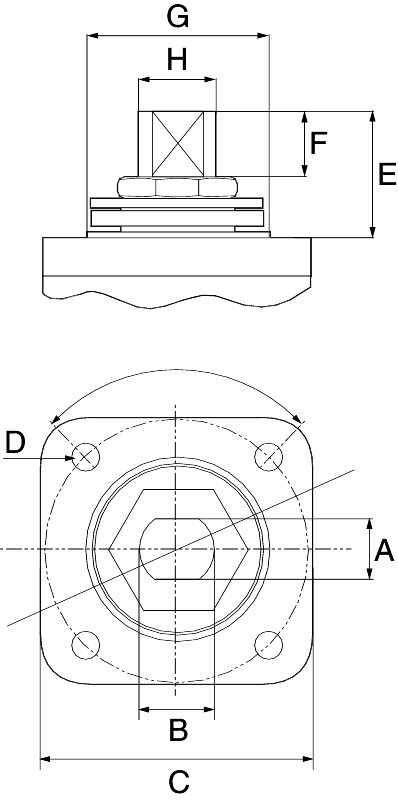

| DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 115 | 120 | 125 | 130 | 140 | 150 | 170 | 180 | 190 | 325 | 350 | 400 | 450 | 500 | ||||||||||||||

| B | 95 | 98 | 112 | 163 | 176 | 186 | 203 | 216 | 215 | 240 | 279 | 307 | 345 | 389 | ||||||||||||||

| C | 160 | 160 | 160 | 213 | 213 | 213 | 300 | 300 | 465 | 715 | 774 | 845 | ** | ** | ||||||||||||||

| Weight | 2,6 | 3,5 | 4,2 | 6,6 | 8,7 | 11,4 | 15,9 | 22 | 35 | 56,6 | 78 | 136 | 242 | 319 | ||||||||||||||

| Measurements in mm, weight in kg. | ||||||||||||||||||||||||||||

| ** With gear. | ||||||||||||||||||||||||||||

| DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 9 | 9 | 9 | 12 | 13 | 13 | 16 | 18 | 20 | 25 | 29 | 32 | ||||||||||||

| C | 50 | 50 | 50 | 50 | 70 | 70 | 70 | 102 | 102 | 125 | 125 | 140 | ||||||||||||

| D | M6 | M6 | M6 | M6 | M8 | M8 | M8 | M10 | M10 | M12 | M12 | M16 | ||||||||||||

| E | 11,5 | 15 | 24 | 32 | 39,5 | 41,5 | 44 | 44,5 | 56,5 | 56 | 56 | 70 | ||||||||||||

| F | 5,7 | 9,2 | 10,2 | 12,2 | 16,2 | 18,2 | 18,1 | 18,7 | 28,5 | 27,6 | 35,2 | 36 | ||||||||||||

| G Æ | 35 | 35 | 35 | 35 | 55 | 55 | 55 | 70 | 70 | 85 | 85 | 100 | ||||||||||||

| Measurements in mm. | ||||||||||||||||||||||||

Two-piece, full-bore ball valve in fire-safe design.

With floating ball for tight shut-off and low pressure drop.

The antistatic and blow-out safe stem according to BS 5351 prevents the stem to blow out at pressure surges.

Mounting flange according to ISO 5211 for actuators is standard. DN 200 and above have double bearings.

AT 3580, the construction length is according to the SSG 1041, 1042.

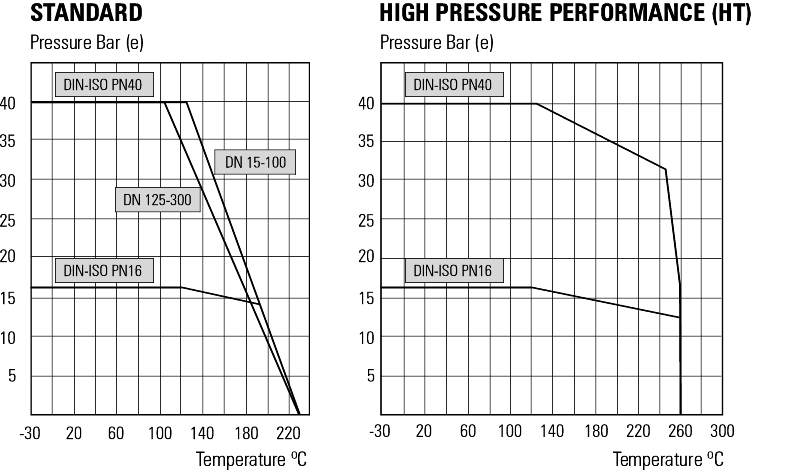

| Fig. no. | DN | Working pressure max. bar | Working temperature max. °C | |||

|---|---|---|---|---|---|---|

| AT 3582 | 15-100 | 40 | 200 | |||

| AT 3582 | 125-300 | 16 | 200 | |||

| AT 3585 | 15-150 | 40 | 260 | |||

| AT 3585 | 200-300 | 16 | 260 | |||

| Pressure and temperature acc. to current standards. | ||||||

| Torque in non pressurised condition and Kvs | ||||||||||||||

| DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nm | 8 | 10 | 15 | 22 | 25 | 40 | 55 | 85 | 130 | 180 | 250 | 340 | 1100 | 1400 |

| KVS | 20 | 40 | 75 | 130 | 170 | 270 | 550 | 1000 | 1650 | 3000 | 4200 | 9000 | 15000 | 20800 |

The valves can be provided with different types of actuators and limit switches (please read seprate data sheet for more information AT 3830, AT 3831, AT3840, AT3841, AT3900)

The valves can also be provided with switches, stem extensions, and in high pressure performance. Construsction length accordint to ANSI B16.10 and with flanges drilled according to ANSI Class 150, 300 and 600.

| Fig. no. | Connection |

| AT 3582 DN 15-100 | Flanges acc. to PN40 |

| AT 3585 DN 15-150 | |

| AT 3582 DN 125-300 | Flanges acc. to PN16 |

| AT 3585 DN 200-300 |

| Example: AT 3582-15 | |||

| AT 35 | 82 | - | 15 |

|---|---|---|---|

| Fig. no. | Material | Additional art. code | DN |

| 82 = Stainless steel, length according to DIN | - = Standard | ||

| 85 = Steel | HT = High temperature |