Ball valve with reduced bore in stainless steel/CPTFE with weld ends or threaded and mounting flange for actuators. Suitable for actuators. Three-piece construction for easy service and maintenance.

| Dimension Range | DN 15 to 100 |

|---|---|

| PN | 125 to 64 |

| Temperature Range | -30ºC to + 260ºC |

| Material | Stainless Steel |

| Article number | Amount |

|---|---|

| AT 3500-10 |

| Dimension range | PN | Temperature range | Material |

|---|---|---|---|

DN 15-100 | 125-64 | -30 - 260 ºC | Stainless Steel |

Shut-off valve mainly for:

- Caustic solutions, acid and salt solutions

- Solvents and alcohols

- LPG, natural gas and petroleum products.

- Warm and cold water, compressed air.

- Saturated steam

PSB.1 Ball Valves

Ball valve in Stainless Steel AT 3500 ..., with reduced bore, weld ends and stainless steel lever. Gasket box of CPTFE.

Ball valve Stainless Steel AT 3520 ..., with reduced bore, threads and stainless steel lever. Gasket box of CPTFE.

Tested according to SS-ISO 5208. Leakage class A applies to this valve type.

The valves are approved by TA-luft

Certificate SS-EN 10204, type 2.2 and 3.1, has to be specified when ordering.

CE-marking

The valves meet the demands from PED, AFS 2016:1, the directive for pressure equipment, according to category III, fluid group 1 and 2. Dimensions to DN 25 satisfies § 8 of the PED, AFS 2016:1.

Surface

Standard surface finish below 3.1 µm for body & ball. Finer surface finish on request.

AT3500/3520 | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Body | Stainless Steel | |||||||||||||

| 2 | Ball | Stainless Steel 1.4401 | |||||||||||||

| 3 | Stem | Stainless Steel 1.4401 | |||||||||||||

| 4 | Body gasket | PTFE | |||||||||||||

| 5 | Seat ring* | PTFE, carbon-filled | |||||||||||||

| 6 | Stem seal | PTFE, glass-reinforced | |||||||||||||

| 7 | Stem gasket | PTFE, carbon-filled | |||||||||||||

| 8 | Centering ring | PTFE, glass-reinforced | |||||||||||||

| Stainless Steel | |||||||||||||||

| 9 | End piece | Stainless Steel 1.4409 | |||||||||||||

| 10 | Lever | Stainless steel | |||||||||||||

| *Also available with Glass-filled PTFE or PEEK. | |||||||||||||||

| Pressure and temperature, reduced bore AT 3500, 3520 | |||||||||

| Seat material | DN 15-32 | DN 40-65 | DN 80-100 | ||||||

|---|---|---|---|---|---|---|---|---|---|

Standard, CPTFE, Carbon filled PTFE 25% | Max. working pressure bar(g)* | 125 (T ≤ 50°C) | 100 (T ≤ 80°C) | 70 (T ≤ 80°C) | |||||

| Max. temperature °C** | 205 (P ≤ 10 bar) | 205 (P ≤ 10 bar) | 200 (P ≤ 10 bar) | ||||||

PEEK | Max. working pressure bar(g)* | 125 (T ≤ 100°C) | 100 (T ≤ 100°C) | 70 (T ≤ 100°C) | |||||

| Max. temperature °C** | 250 (P ≤ 10 bar) | 245 (P ≤ 10 bar) | 235 (P ≤ 10 bar) | ||||||

PTFE, glasfiberarmerad | Max. working pressure bar(g)* | ||||||||

| Max. temperature °C** | |||||||||

Pressure and temperature acc. to applied standards. Note that the pressure- and temperatures above is not related. *Max pressure bar(g) up to specified temperature. **Max temperature °C up to the specified pressure. | |||||||||

| Torque | ||||||||||||||||||||||||

| DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nm | 9 | 11 | 12 | 19 | 28 | 37 | 52 | 68 | 100 | |||||||||||||||

Torque above is applied for all seating material avaiable, CPTFE, PEEK or Glass-filled PTFE | ||||||||||||||||||||||||

| Kv-value reduced and full bore | |||||||||

| DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 |

|---|---|---|---|---|---|---|---|---|---|

| KVS | 6,9 | 12,7 | 29,2 | 48,2 | 73,1 | 107,5 | 215 | 275,2 | 498,8 |

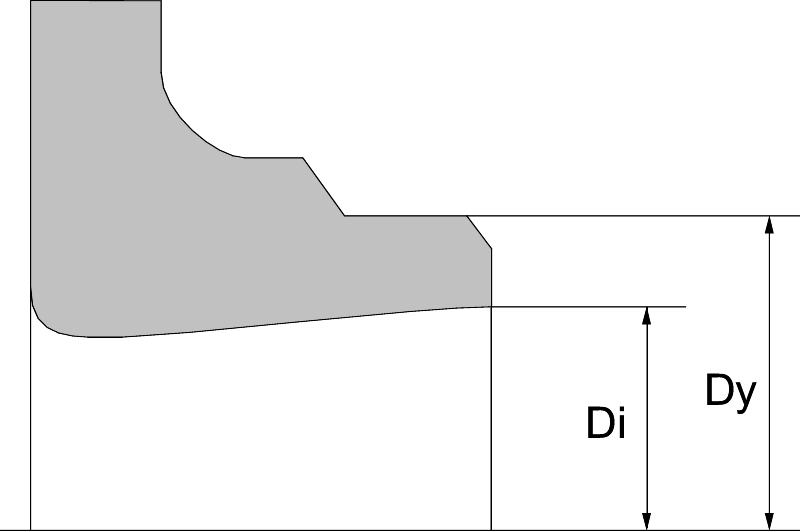

| AT 3500 Meassurements welded ends | |||||||||

| DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 |

|---|---|---|---|---|---|---|---|---|---|

| Dy | 21,3 | 26,9 | 33,7 | 42,4 | 48,3 | 60,3 | 76,1 | 88,9 | 114,3 |

| Di | 18,1 | 23,7 | 29,7 | 38,4 | 44,3 | 55,1 | 70,9 | 83,7 | 109,1 |

| Material thickness | 1,6 | 1,6 | 2,0 | 2,0 | 2,0 | 2,6 | 2,6 | 2,6 | 2,6 |

| AT 3520 Measurements BSP threads | ||||||||||||||

| DN | 15 | 20 | 25 | 32 | 40 | 50 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| G | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | ||||||||

| E | 20,95 | 26,44 | 33,25 | 41,91 | 47,8 | 59,61 | ||||||||

| K | 16,5 | 17,5 | 20,5 | 20,5 | 24,5 | 25,5 | ||||||||

| W | 27 | 33 | 41 | 51 | 56 | 68 | ||||||||

| No. of threads | 14 | 14 | 11 | 11 | 11 | 11 | ||||||||

Measurements in mm. | ||||||||||||||

Can be provided with different types of actuators and limit switches. (See separate datasheet AT 3830, AT 3831, AT3840, AT3841, AT 3940, AT 3941, AT 3910, AT 3911). Can also be supplied with stem extensions and dead-mens handle (open or close).

Other ends available:

Weld ends:

Threaded ends:

Special executions:

| DN | AT 3500, weld ends | AT 3520, threads | AT 3547 | |

|---|---|---|---|---|

| Article No. | RSK-No. | Article No. | RSK-No. | |

Options:

Seals:

FS = Fire-safe

GF = 25% glass-filled PTFE

PEEK = Seats in PEEK-material

See separate Pressure/temperature diagrams for differents seats.

Anslutningar:

DIN = Weld ends acc. DIN/SCH40

SMS = Weld ends acc. SMS3008

NPT = NPT-threads

Exemple:

AT 3500-25FS (Fire-safe execution)

AT 3500-25GF (Seats of glass-filled PTFE)

AT 3520-25PEEK (Seats of PEEK)

AT 3500-25DIN (Weld ends acc. DIN3239, 1 and 2)

AT 3500-25SMS (Weld ends acc. SMS3008 )

AT 3520-25NPT (NPT-threads)