Stainless steel strainer for warm water, cooling systems, oil and corrosive fluids.

| Dimension range | DN 150-500 |

|---|---|

| PN | 10 |

| Temperature range | -30 °C to +110°C |

| Material | Stainless steel |

| Article number | Amount |

|---|---|

| AT 4054A150. | |

| AT 4054A200. | |

| AT 4054A250. | |

| AT 4054A300. | |

| AT 4054A350. | |

| AT 4054A400. | |

| AT 4054A500. |

| Dimension range | PN | Temperature range | Material |

|---|---|---|---|

| DN 150 - 500 | 10 | -30 °C to 110 °C | Stainless steel |

For mechanical cleaning of warm water, cooling systems, oil and corrosive fluids.

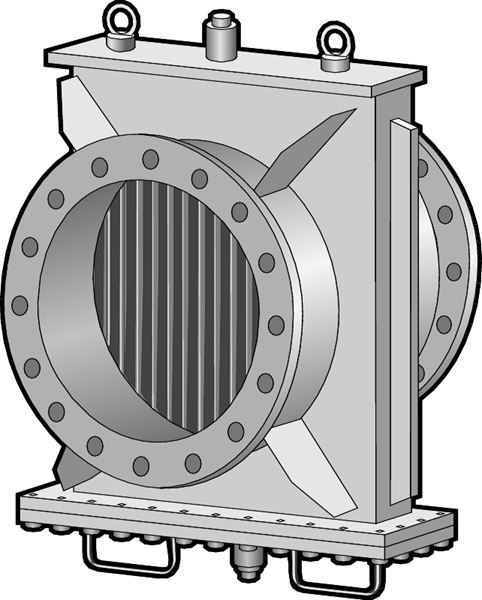

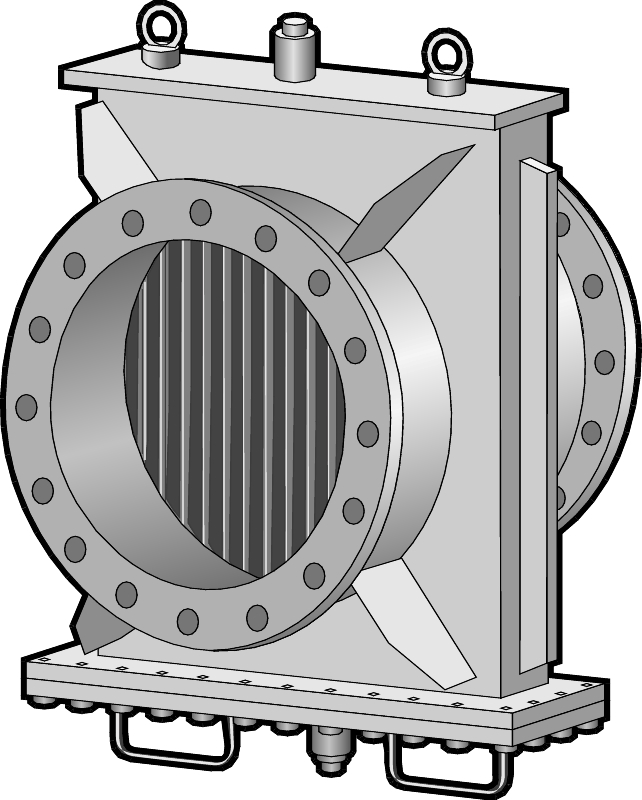

PMB.211 Screen filter

Strainer AT 4054A. Stainless steel, straight bore, with flanges, PN 10. Mesh width ... mm.

Quality certificate SS-EN 10204, 2.2 (if stated in the order).

The mechanic calculations for the strainer does not take external forces into consideration.

CE-marking

AT 4054A meet the requirements of 8§ in AFS 2016:1 and 2014/68/EU (Pressure Equipment Directive).

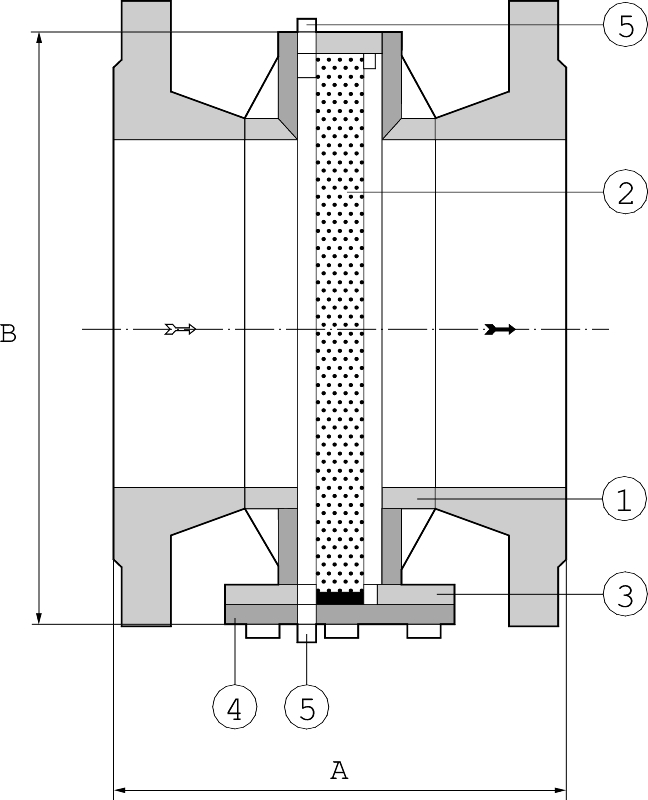

| Pos | Component | AT 4054A |

|---|---|---|

| 1 | Body | Stainless steel 1.4301 |

| 2 | Sieve | Stainless steel 1.4301 |

| 3 | Cover gasket | O-ring Viton |

| 4 | Cover | Stainless steel 1.4301 |

| 5 | Drain plug | Stainless steel 1.4301 |

| DN | 150 | 200 | 250 | 300 | 350 | 400 | 500 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A Flanges | 350 | 400 | 450 | 500 | 550 | 600 | 700 | ||||||||||||

| A Weld ends | 240 | 276 | 310 | 344 | 385 | 430 | 520 | ||||||||||||

| B | 475 | 475 | 475 | 475 | 595 | 595 | 595 | ||||||||||||

| Width | 450 | 450 | 450 | 450 | 640 | 640 | 640 | ||||||||||||

| Weld end Od | 168,3 | 219,1 | 273 | 323 | 355,6 | 406,4 | 508 | ||||||||||||

| Drain plug | G 3/4 | G 3/4 | G 3/4 | G 3/4 | G 1 | G 1 | G 1 | ||||||||||||

| Weight | 85 | 95 | 117 | 124 | 200 | 220 | 280 | ||||||||||||

| Measurements in mm, weight in kg. | |||||||||||||||||||

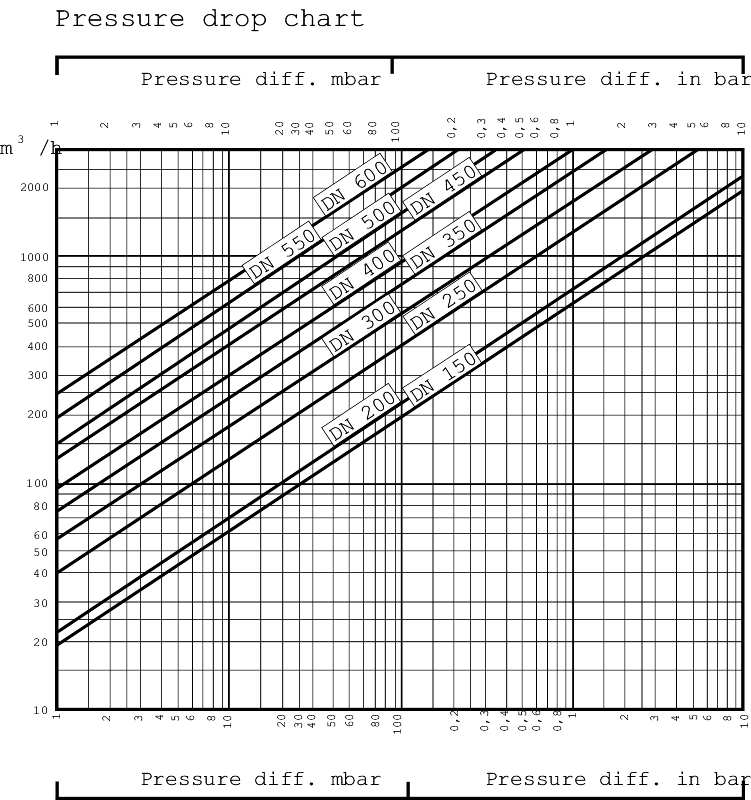

Effectively catches the solid particles that are larger than the perforation in the strainer insert. The insert is made of folded perforated steel, with a large free strainer area in relation to DN which gives a low pressure drop. Standard perforation is 1,0 mm for DN 150-300 and 2,0 mm for DN 350-500. Face to face dimension according to DIN 3202/1, F5 for the flanged version.

| DN | 150 | 200 | 250 | 300 | 350 | 400 | 500 |

|---|---|---|---|---|---|---|---|

| KVS | 575 | 710 | 1240 | 1740 | 2350 | 2760 | 4660 |

| DN | Maximum pressure bar(g) | Working temp min/max °C | |

|---|---|---|---|

| AT 4054A | 150-500 | 10 | -30/110 |

Can be delivered with other perforations: 3,0, 5,0, 8,0, 10,0 mm.

| Fig. No. | Connection |

|---|---|

| AT 4050AHT | Flanges acc. to SS 336-PN 25 |

| AT 4051AHT | Welded ends |

| AT 4054A | Flanges acc. to SS 335-PN 10 |

| AT 4055A | Welded ends |

The strainer should be mounted in horizontal pipe for best function and easier cleaning of the strainer insert. Can be mounted with the cover either downwards or upwards as there is a drain plug in both ends. Note that the flow has to be according to the flow arrow on the strainer body.

Blow-out valves, for example AT 3600 or AT3535, can be mounted instead of the drain plug for simpler cleaning.

| Example: AT 4051A500 | |||

| AT 4051A | 500 | ||

|---|---|---|---|

| Fig.No. | DN | ||

| AT 4050AHT = flanges, steel | 150-500 | ||

| AT 4051AHT = welding ends, steel | 150-500 | ||

| AT 4054A = flanges, stainless steel | 150-500 | ||

| AT 4055A = welding ends, stainless steel | 150-500 |