Ductile iron strainer with flanges, PN 16. Stainless steel strainer insert with mesh width 0,6 mm. For warm water, hot water, steam, condensate and petrolium products as well as glycol-based cooling systems.

| Dimension range | DN 15 to DN 250 |

|---|---|

| PN | 16 to 25 |

| Temperature range | -10 °C to +350 °C |

| Material | Ductile iron |

| Article number | Amount |

|---|---|

| AT 4029B15 | |

| AT 4029B20 | |

| AT 4029B25 | |

| AT 4029B32 | |

| AT 4029B40 | |

| AT 4029B50 | |

| AT 4029B65 | |

| AT 4029B90 | |

| AT 4029B100 | |

| AT 4029B125 | |

| AT 4029B150 | |

| AT 4029B200 | |

| AT 4029B250 | |

| AT 4029B300 |

| Dimension range | PN | Temperature range | Material |

|---|---|---|---|

DN 15 - 250 | 16 | -10°C to +350°C | Ductile iron |

Strainer for mechanical cleansing of warm-, hot- and cooling water, petroleum products, neutral fluids and steam.

PMB.211 Strainer

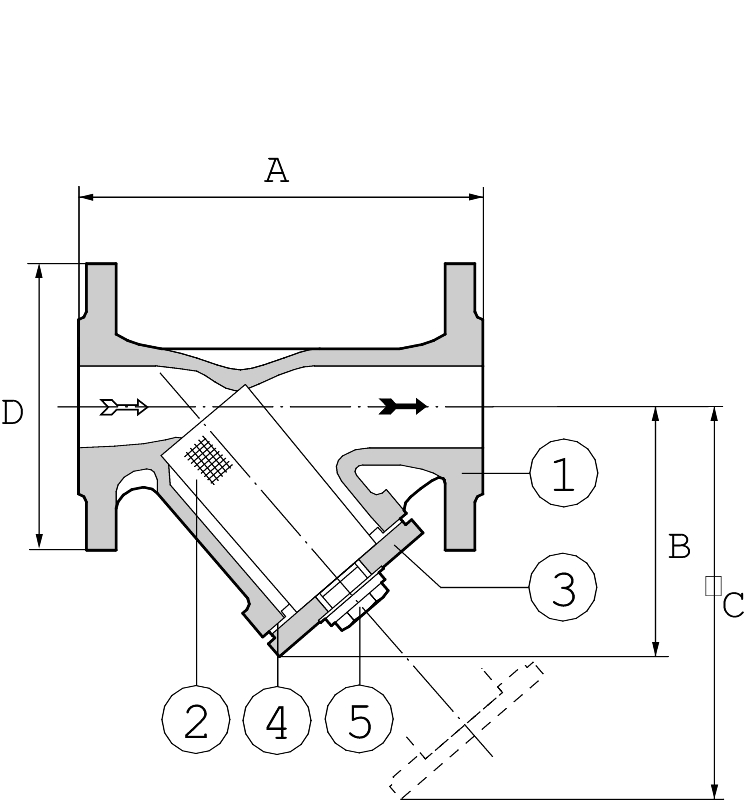

Strainer AT 4029B, DN ... body made of ductile iron, PN 25/16, with differntial pressure measurement sockets, flanges. Mesh width, 0,6 mm.

The differential outlets are located on the top.

| Pos | Component | AT 4029B |

|---|---|---|

| 1 | Body | Ductile iron EN-GJS-400-18LT |

| 2 | Strainer insert | Stainless steel 1.4301 |

| 3 | Cover | Ductile iron EN-GJS-400-18LP |

| 4 | Cover gasket | Graphite CrNiSt |

| 5 | Cleaning plug / | Steel C35E |

| Diff.pressure plug |

| DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 130 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | ||||||||

| B | 90 | 100 | 115 | 135 | 150 | 155 | 175 | 205 | ||||||||

| C | 135 | 150 | 180 | 215 | 240 | 250 | 285 | 330 | ||||||||

| D AT 4028B | 95 | 105 | 115 | 140 | 150 | 165 | 185 | 200 | ||||||||

| D AT 4029B | 95 | 105 | 115 | 140 | 150 | 165 | 185 | 200 | ||||||||

| Size: cleaning plug | G3/8 | G3/8 | G3/4 | G3/4 | G1 | G1 | G1 | G1 | ||||||||

| Diff. pressure plug | G1/4 | G1/4 | G1/4 | G1/4 | G3/8 | G3/8 | G3/8 | G3/8 | ||||||||

| Height strainer insert | 56 | 68 | 82 | 98 | 114 | 119 | 134 | 149 | ||||||||

| Diam. strainer insert | 23 | 28 | 36 | 42 | 50 | 61,5 | 78,5 | 89,5 | ||||||||

| Cover gasket, Dy | 46 | 46 | 56 | 68 | 79 | 87 | 102 | 122 | ||||||||

| Cover gasket, Di | 36 | 36 | 46 | 56 | 68 | 75 | 90 | 110 | ||||||||

| Weight AT 4028B | 2,6 | 3,0 | 4,3 | 6,8 | 8,8 | 11,0 | 14,6 | 18,6 | ||||||||

| Weight AT 4029B | 2,6 | 3,0 | 4,3 | 6,8 | 9,0 | 11,0 | 14,6 | 18,6 | ||||||||

| Dimension in mm, weight in kg | ||||||||||||||||

| DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

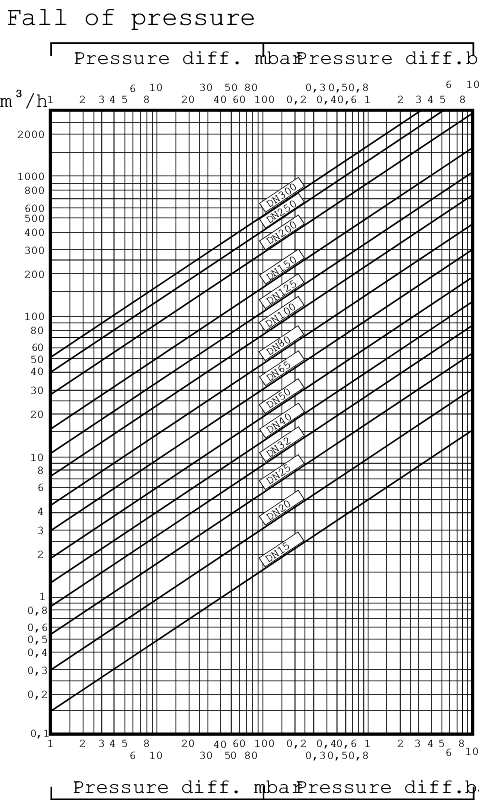

| KVS | 6,2 | 9,6 | 14,2 | 23,1 | 36,6 | 53,7 | 95,1 | 137,1 | 206,4 | 268,8 | 401 | 706 | 1229 |

| Pressure and temperature Acc. to DIN EN 1092-2:1997 with the following max-values: | ||||||

| AT 4029B, DN 15-50, PN 25 | AT 4029B, DN 65-350, PN 16 | |||||

|---|---|---|---|---|---|---|

| Min/Max working temperature | Max. working pressure. | |||||

| °C | bar | bar | ||||

| -10 | 25 | 16 | ||||

| 120 | 25 | 16 | ||||

| 150 | 24,3 | 15,5 | ||||

| 180 | ||||||

| 200 | 23 | 14,7 | ||||

| 230 | ||||||

| 250 | 21,8 | 13,9 | ||||

| 300 | 20 | 12,8 | ||||

| 350 | 17,5 | 11,2 | ||||

| *) NOTE! AT 4029B is in design PN 16, DN 65-250 | ||||||

The insert gaskets standard mesh width is 0,6 mm. On request, the strainer can be provided with alternative mesh sizes, such as:

0.1, 0.25, 0.5, 1.0, 1,5, 2.0, 3.0, 5,0 and 8.0 mm.

Internal and external powder-coated epoxi is used for installations with hygiene requirements for water intended for human consumption or where there is a requirement for internal corrosion protection: AT 4028BE,

For differential pressure measurement across the filter, strainer DN 15-32 connection G 1/4. DN 40 and larger have connection G 3/8. See AT 1812.

For installation in cooling systems, the filters are available with external rust-preventing, according to system AT 1012.

In a horizontal pipe the strainer should be mounted with the cover downwards. Not that the flow has to be according to the flow arrow. The strainer can be vertically mounted with a downwards flow.

A blow-out valve, e.g. AT 3535A or AT 3591, can be mounted instead of a clean-out plug for an easier purge of the strainer insert.

| Fig. no. | Flanges acc.to | |

|---|---|---|

| AT 4029B | DN 15-50 | SS EN1092-PN 25 |

| DN 65-200 | SS EN1092-PN 16 |

Highly increased pressure drop across the filter indicates that the strainer insert should be cleaned.

Strainer inserts AT 4028AF and cover gaskets AT 4028AL and AT 4028BL are available as spare parts.

Manufacturer, DN, PN, material and flow arrow.

Marking in the body according to:

- AT 4028B, JL1040

- AT 4029B, JS1025

| Example: AT 4028B50 | ||

| DN | AT-no | RSK-no |

|---|---|---|

| 15 | 4028B15 | 506 29 00 |

| 20 | 4028B20 | 506 29 01 |

| 25 | 4028B25 | 506 29 02 |

| 32 | 4028B32 | 506 29 03 |

| 40 | 4028B40 | 506 29 04 |

| 50 | 4028B50 | 506 29 05 |

| 65 | 4028B65 | 506 29 06 |

| 80 | 4028B80 | 506 29 07 |

| 100 | 4028B100 | 506 29 08 |

| 125 | 4028B125 | 506 29 09 |

| 150 | 4028B150 | 506 29 10 |

| 200 | 4028B200 | 506 29 11 |

| 250 | 4028B250 | 506 29 12 |

| 300 | 4028B300 | 506 29 13 |

| Example: Strainer AT 4029A50 | ||

| DN | Art.no. | RSK-no |

| 15 | 4029A15 | 506 29 14 |

| 20 | 4029A20 | 506 29 15 |

| 25 | 4029A25 | 506 29 16 |

| 32 | 4029A32 | 506 29 17 |

| 40 | 4029A40 | 506 29 18 |

| 50 | 4029A50 | 506 29 19 |

| 65 | 4029A65 | 506 29 20 |

| 80 | 4029A80 | 506 29 21 |

| 100 | 4029A100 | 506 29 22 |

| 125 | 4029A125 | 506 29 23 |

| 150 | 4029A150 | 506 29 24 |

| 200 | 4029A200 | 506 29 25 |

| 250 | 4029A250 | 506 29 26 |