Automatic air-/particle separator of steel. Gas-/particle separator and dirt protection.

| Dimension range | DN 50 to DN 150 |

|---|---|

| PN | 10 |

| Temperature range | 0 °C to 110 °C |

| Material | Steel |

| Dimension range | PN | Temperature range | Material |

|---|---|---|---|

DN 50-150 | 10 | 0 °C to 110 °C | Steel |

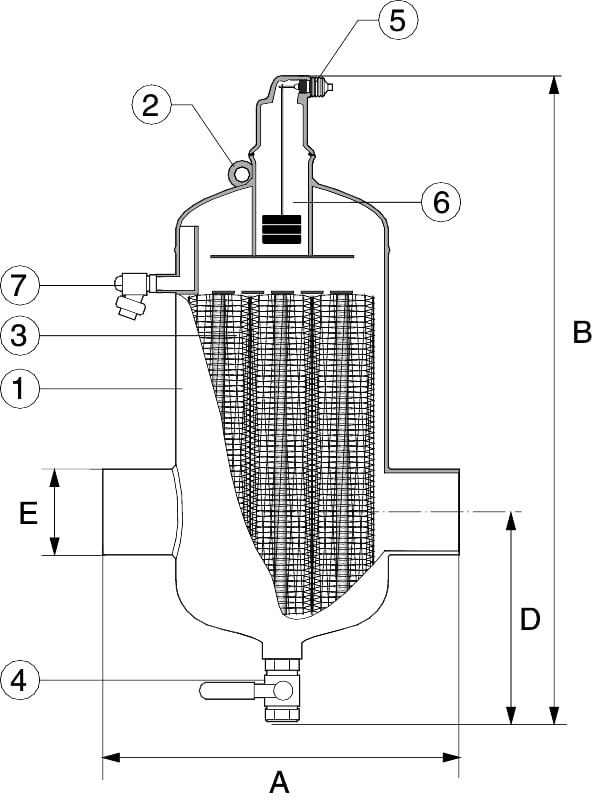

| 1 | Body and ends of steel, with weld ends or flanges PN16. |

| 2 | Lifting-loops to ease at installation |

| 3 | The spirotube is designed to separate even the smallest microbubbles. |

| 4 | Manual air valve for removal of large volumes of air at comissioning |

| as well as edge drainage for liquid pollutants. | |

| 5 | Automatic air valve supplied with 15mm extraction. Threaded exhaust |

| the air valve does't leak and con not be closed | |

| 6 | The ventilation mechanism is located in a separate chamber protected from dirt. |

| 7 | Large dirt chamber makes it rarely need to drain. |

| 8 | Drain. |

| Connection | 50 | 65 | 80 | 100 | 125 | 150 |

|---|---|---|---|---|---|---|

| A | 260 | 260 | 370 | 370 | 525 | 525 |

| B | 630 | 630 | 785 | 785 | 1045 | 1045 |

| D | 265 | 265 | 345 | 345 | 480 | 480 |

| E (welded ends) | 60,3 | 76,1 | 88,9 | 114,3 | 139,7 | 168,3 |

| E (flanges) | 50 | 65 | 80 | 100 | 125 | 150 |

| Weight (weld/flange) | 12/17 | 12/18 | 30/38 | 30/40 | 70/83 | 70/86 |

| Dimensions in mm, weight in kg |

The uniqe construction removes loose air as well as dirt particles. The surface magnifier generates motionless zones above and below the flow. The air rises in the motionless zone to be collected in the air chamber and is then released through the automatic valve. Dirt particles that are heavier than water settles and is collected in the dirt chamber to flush out the system through the drain valve. This can be done during full operation. The velocity decreases as the fluid flows into the separation body. Free gas bubbles, particles and sludge separates while passing through the separator.

Separate bubbles lifts and enter the float body. The liquid level goes down and the float sinks. When the float, that is conneced to the separation mehcanism via a bar, reaches a certain level, the mechanism is affected and air can flow into the free. When the float rises again, the mechanism closes.

The large volume of the air chamber and special design makes the liquid level never reach the drainage mechanism, even if the air in the chamber is compressed to 10 bar.

| Connection | 50 | 65 | 80 | 100 | 125 | 150 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max flow m³/h | 8 | 15 | 20 | 30 | 50 | 75 | |||||||||

| Pressure drop bar | 0,015 | 0,020 | 0,018 | 0,013 | 0,016 | 0,017 | |||||||||

| Values above apply at max. speed 1 meter/second. | |||||||||||||||

Since the micro bubbles are released at the hottest point in the plant, the component should be placed on the hottest spoint in the system.

In a heating system the supply line is often the warmest spot in the plant.

In a heating system, the warmest point is usually on the supply line, as close to the heater as possible. In order to maintain a good absorption effect, the static pressure at the site of installation should not exceed 15-20mvc.

Marked with dimension, max. operating pressure, max. operating temperature and the manufacturers name