Compact heating meter, AT 7500F threaded or flanged connection, complete with paired Pt500 temperature sensor, integrator with LCD display, and ultrasonic thermal meter. Cord operation 230VAC. For measuring of thermal energy in heat or cooling systems with water as heat carrier. Not suitable for glycol mixes or other anti-icing additives. The meter meets the demands according to SS-EN1434.

| Dimension range | DN 15-100 |

|---|---|

| PN | 16/25 |

| Temperature range | +5ºC to +105ºC |

| Material | Brass/Cast iron |

| Article number | Amount |

|---|---|

| AT 7500FG15-1,5 | |

| AT 7500FG20-2,5-130 | |

| AT 7500FG25-6 | |

| AT 7500FG40-10 | |

| AT 7500F20-2,5 | |

| AT 7500F25-6 | |

| AT 7500F40-10 | |

| AT 7299-15INST | |

| AT 7299-20INST | |

| AT 7279-45 | |

| AT 7279-52 | |

| AT 7275EW-M | |

| AT 7275EW-P | |

| AT 7275EW-AN | |

| AT 7500F-BAT |

| Dimension range | PN | Temperature range | Material |

|---|---|---|---|

| DN 15-100 | 16/25 | +5ºC to + 105ºC | Brass/Cast iron |

The meets the demand from SS-EN1434 MID class 2, and performance according to SWEDAC 2006:4- Certified by registered body LEI, certification number LT-1621-MI004-PTB013.

CE-marking

According to MID 2004/22/EG

| Components | Material | |

|---|---|---|

| 1 | Meter body | Brass/Cast iron (DN50-100) |

| - Connection (thread/flange) | Brass/Cast iron (DN50-100) | |

| 2 | Membrane to ultra sound element | Stainless steel 1.4435 |

| 3 | O-ring | EPDM 70 Shore A |

| 4 | Integrator protection | Polycarbonate |

| 5 | Temperature sensor | |

| - Protection sleeve | Stainless steel 1.4435 | |

| - Connection cable | Silicone |

| Threaded connection, permanent flow qp 1,5 to 10 | |||||||||||||

| Permanent flow qp (m3/h) | 1,5 | 2,5 | 6 | 10 | |||||||||

| Connection after gauge coupling | DN 15 | DN 20 | DN 25 | DN 40 | |||||||||

| Build length | 110 | 130 | 260 | 300 | |||||||||

| Weight | 0,8 | 0,9 | 1,5 | 3,0 | |||||||||

| Meter thread * | G 3/4" | G 1" | G 1 1/" | G 2" | |||||||||

Measurements in mm, weight in kg *) The gauge's thread is one size larger than connection after gauge coupling | |||||||||||||

AT 7500F is a ultasonic thermal energy meter for measuring thermal energy in heating and cooling facilities with water as fluid (not glycol). Ideally for, as an example, district heating and 6oC/12°C cooling systems. The meter consists of a flow meter of ultrasonic type, paired PT 500 temperature sensors and a separate electronic integrator with multifunction LCD display for display of accumulated energy and volume. There is also a possibility to read instantaneous values for flow, effect, temperature for inlet, return and temperature difference, max and minium values, and self test with error indication.

AT7500F has a flow meter of ultra sound type, without movable parts. This means that it is free from parts that can be worn out and, since it doesn't have any magnetic parts, is not sensitive of water with a high magnetite content. The flow meter is of direct ultrasonic type according to the duration difference method with an integrated sensor and receiver in each end of the meter pipe. Every measure cycle (one per second) is started by the up stream sensor sending an ultra sound impulse to the down stream receiver/sensor. The time interval between sent and recieved sgnal is calculated very precisesly by the flow meter. After that the sensors change function. The original receiving sensor now becomes the sending sensor and the ultrasonic signal is sent in the opposite direction. Once again the time interval between sent and received signal is calculated. The time interval in the flow direction is quicker than against the flow. By comparing this time difference the ultrasonic meter can accurately calculate the flow. The flow value is integrated with with the temperature loss over the circuit and the so called s k K-factor, which is calculated and presented as energy amount on the display.

The meters are delivered as a standard with mains supply operation but battery operation is available as an option. The meter should always be installed in the colder pipe line, in other words the return pipe line in heating systems and the input pipe line on coolings systems.

The meter can be supplemented with a remote reading module of the type M-bus, pulse or 4-20 mA signal.

| Flow meter | DN | 15 | 20 | 25 | 40 | 50 | 65 | 80 | 100 |

|---|---|---|---|---|---|---|---|---|---|

| Nominal flow, qp | m³/h | 1,5 | 2,5 | 6 | 10 | 15 | 25 | 40 | 60 |

| Max flow, qs | m³/h | 3 | 5 | 12 | 20 | 30 | 50 | 80 | 120 |

| Minimum flow, qi | m³/h | 0,006 | 0,010 | 0,024 | 0,04 | 0,06 | 0,1 | 0,16 | 0,24 |

| Start flow | l/h | 2,5 | 4 | 7 | 20 | 40 | 50 | 80 | 120 |

| Overload flow | m³/h | 4,6 | 6,7 | 18,4 | 24 | 36 | 60 | 90 | 132 |

| Pressure loss by qp | mbar | 75 | 100 | 128 | 140 | 140 | 75 | 80 | 75 |

| Dynamic measuring area (qp/qi) | 250:1 | 250:1 | 250:1 | 250:1 | 250:1 | 250:1 | 250:1 | 250:1 |

| Pressure and temperature | |

| Pressure | max 16 bar, max 25 bar flanged version |

| Temperature range | + 5°C to + 105°C |

| Measuring cycles (specified in seconds) | |

| Volume | |

| Corded operation | 1/8 sec |

| Battery | 1 sec |

| Temperature | |

| Corded operation | 2 sec |

| Battery | 16 sec |

| Energy, effect | 2 sec |

| LCD | 2 sec |

| Measuring characteristics | |

| Normal flow qp - minimum flow qi | 250:1 (all models) |

| Max flow qs - normal flow qp | 2:1 (all models) |

| Temperature range media | + 5 - +105 °C |

| Accuracy | Class 2 according to EN 1434-1 (all models) |

| Integrator | |

| Temperature range, T | 1- +180 °C |

| Temperature difference range, ∆T | 3-177 K |

| Electromagnetic environment class | Class E 1 |

| Mechanical environment class | Class M 1 |

| Surrounding temperature | 5-55 °C |

| Storage temperature | -25 - 70 °C |

| Protection class | IP 54 (only flow sensor IP 68) |

| Display | LC-display with 8 figure display with alternative symbols |

| Measure unit of consumed energy | kWh / MWh |

| Temperature sensor | PT 500, dual wire connection |

| Energy consumption | 230 VAC as an option 3,6 vDC lithium battery. |

| Communication ports for remote reading | 2 st |

| Data ports | - Optic (according to EN 61107, |

| data protocol according to EN 60870-5) | |

| Length of cable between integrator and flow gauge | 1,5 m (DN15-20) 3m (DN25-100) |

| Measurements (BxHxD) | 100x90x54 mm |

| Temperature sensor, paired | |

| Resistance elements | Platina Pt 500 according to DIN EN 60751 |

| Temperature range | -20- +150 °C |

| Insert length/diameter, standard | |

| Threaded meter DN 15 - DN 40 | DN 15-25 45 mm/5,2 mm, 2 m |

| Flange meter DN 20-40 | DN 20-25 45 mm/5,2 mm |

| Flange meter DN 50-100 | DN 50-100 45 mm/5,2 mm |

| PTB approval | K 7.2 |

The comsumption register is shown on a 8 figure LCD where the values for energy, effect, volume, volume flow, temperature inlet and return, split T and eventual error code is displayed.

The necessary settings and changes are possible when the optical interface or through M-bus.

The energy meter has a LCD-display with 8 figures for main values and 6 different menus. Through a simple button press on the rise key (black button) you will be moved between different measure values within a menu group. To cyclically browse between the 6 different menu groups you hold the rise key (black button) down for 3-4 seconds.

The six different menus that are shown are specified below:

1: Main menu

- Accumulated consumption (energy volume)

- Instantaneous values (effekt, flow, temperature, delta T)

2: Reading menu

- Consumption values on a specific date

3: Information menu

- Software version

- Current date and time

- Next target day

- Settings of tariff values

- Breaking point settings between heating and cooling gauging

- adjusted M-Bus addresses

4: Pulse values

- Pulse input 1 and 2 (pulse numbers)

- Pulse output 1 and 2 (pulse numbers)

5: Tariff menu

6: Month menu

- Monthly consumption values

7. Cooling register

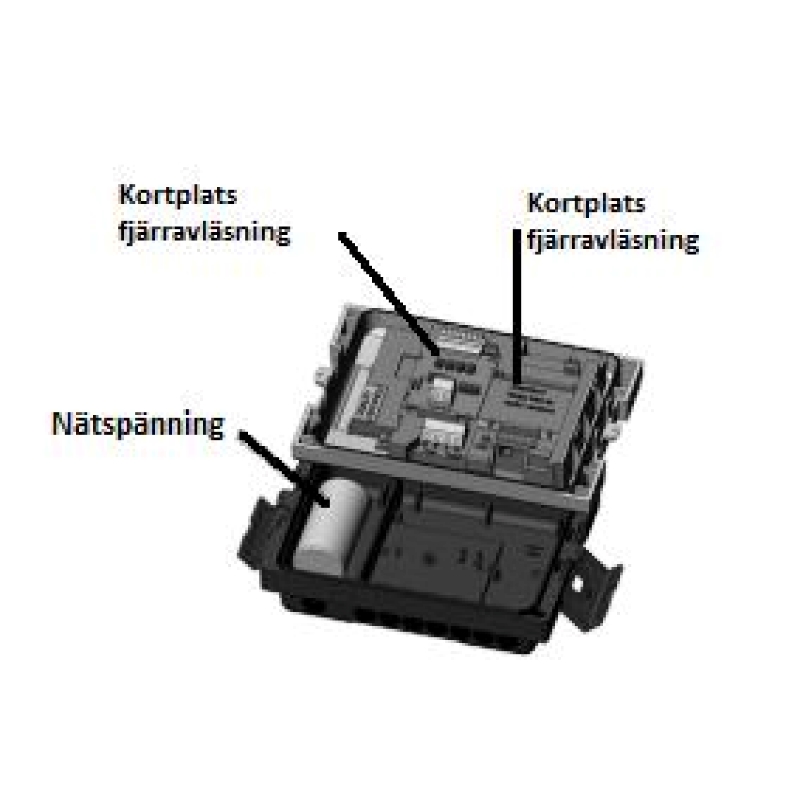

For remote reading of measure values and connection to DUC/superordinate control system etc. there are several plugin modules for the energy meter. The integrator is provided with two card slots for remote reading modules. 2 M-bus cards, 2 pulse cards or 1 M-bus card and 1 pulse card can be installed at the same time. For analog remote reading only one card can be used.

The following modules can easily be installed without damaging the verification seal:

M-bus module according to EN 13757, AT 7275EW-M

For remote reading through the M-bus of the meter's effect, flow, temperature etc. It's done though the module's primary or secondary address with a M-Bus master or a level converter (300 or 2400 Baud.). The primary address is, when newly installed, set to "000" in port 1 (right slot) and last two digits in serial number for port 2 (left slot). This can be changed to an address from "001" to "250". The secondary address represents the meter's manufacturing number in a 8 figure serial number. Both addresses can be programmed in the meter or through the M-buss loop and service software Izar Mobile.

If AT 7500F is rebuilt to battery operation, it is reocommended to set the M-Bus to read the meter at most once per hour.

Analog module, AT 7275EW-AN

For remote reading through analod 4-20mA signal with two programmable passive outputs, used for frequent measure readings.

Remote reading output/pulse input AT 7275EW-P

For remote reading through pulse of the meter's volume and/or heat quantity. The meter has two open-collector connections bounce free for counting of pulses in an external counter or superordinate systems. By delivery the heating meter is configured with 2 outputs.

Optical interface

An optical data port are also available as a standard and can be used for reading or parameterizethe gauge through a PC and service soft ware (e.g. IzarSet).

| Specification pulse output | |

| Pulse length | roughly 125 ms +/- 10% |

| Max voltage | 3-30 V DC |

| Max current | 0,02 A |

| Nominal size qp | Pulse value | Pulse value |

| (m3/h) | Energy | Volume |

| 1,5 to 10 | 1 kWh (0,001 MWh) | 10 liters (0,010 m³) |

| 15 to 60 | 1 kWh (0,001 MWh) | 100 liters (0,100 m³) |

| Accessories | Order number |

|---|---|

| Couplings (2 per meter) for G 3/4 (is also a part of the installation kit below) - G 2 | AT 7056A15, 7056-20 /-25 /-40 x 2 st |

| Stainless steel thermal well G 1/2 | |

| 45 mm (is also a part of the installation kit below) | AT 7279-45 (1st DN15-20, 2st DN25) |

| 52 mm | AT 7279-52 (2st DN40) |

| 85 mm | AT 7279-85 (2st DN50-100) |

| Ball valve with inner thread. for 27,5 alternatively 45 mm temperature sensors | Se AT 7278 |

| Nickel-plated brass. G 1/2-G 1 | |

| Installation kit for qp 1,5 (DN 15). Contains: | AT 7299-15INST |

| - 2 G 3/4 meter couplings with gaskets | |

| - 1 thermal well (45 mm) | |

| - 1 110 mm spud | |

| Installation kit for qp 2,5 (DN 20). Contains: | AT 7299-20INST |

| - 2 G 1 meter couplings with gaskets | |

| - 1 thermal well (45 mm) | |

| - 1 130 mm spud | |

| Transition piece | AT 7055R20-25 |

| to obtain 130 mm G 1 build length from 110 mm G 3/4 | |

| Remote reading modules | |

| M-Bus module for remote reading according to interface EN 13757-3 | AT 7275EW-M |

| Pulse module for remote reading via open collector pulse | AT 7275EW-P |

| Analog signal for communication through analog signal 4-20 mA | AT 7275EW-AN |

| Spare parts | |

| Temperature sensor paired Pt 500, cable length 2 m. Length 45 mm | AT 7276-45PT500 |

| Batteri 3,6 volt battery for battery powered unit | AT 7500F-BAT |

| Options | ||

|---|---|---|

| Compact meter | ||

| - in flanged performance *) | AT 7500F... | |

| *) See the section how to order | ||

erDuring the meter installation it should be taken in to account that the measuring is done correctly metrologically, and that it is service and reading friendly. The flow meter should be mounted in the pipe line that has the lower temperature, i.e. for heating systems in the return pipe and in cooling systems in the inlet pipe. If the meter is installed on the wrong pipe line the meter is no longer type approved, the measured values are not trustworthy, faulty or they may be missing entirely. During installation in the wrong pipe line the error code "E3" will be shown. Some configuration adjustment of installation in warm pipe line can not be done, a new meter has to be ordered.

The flow meter can be mounted both horizontally and vertically. A straight line before or after the meter isn't necessary, but a calm undisturbed straight line of 3xDN before the meter is recommended to obtain a good and stable flow profile. The flow meter should be placed on a low point to prevent the effect of air in the system. The placement of the flow meter should also not be directly after a vent or before a pump. It is recommended to install a shut down valve before and after the meter to facilitate an possible replacement of the meter. The meter is recommended to be installed horizontally with the meter pipe tilted 45° to the side.

Note! Meters with threaded connection is only intended for flat seal with required water meter couplings and fiber gaskets, e.g. AT 7056. Threaded joint with, as an example, flax or corresponding seal can not be used.

By media temperature over 90oC, or by contant high surrounding temperature (over 55oC) the electronic parts (integrator) should be mounted in an environment with room temperature. The standard performance has a 1,5 m between integrator and flow sensor. This cable can not be cut or spliced since the integrator and flow sensor are calibrated and certified as a unit. If the cable is cut the compact meter will not work and will need to be replaced by a new compact meter. The integrator is prepared for wall mounting.

Thermowell is used for mounting in G 1/2 pipe sleeve is used with advantages lika: For working protection and facilitate replacement of temperature sensor without needing to drain the system. In the DN15 and DN20, one temperature sensor is already pre-mounted in the flow sensor.

Connection of temperature sensors with dual wire connection.

The sensors are marked with blue and red color marking respectively for mounting in cold and hot flow line respectively. The sensor's/thermal well's tip should be placed in the middle of the flow.

For detailed information please see the installation section.

The meter has a NOWA compatible verification for revision of an accredited cotrol body or laboratorium after expiration time.

The replaceable units in the meter is the remote reading module and the temperature sensor.

| Flanged performance, corded operation, installation in colder pipe lines | ||||||||

| AT-no | qp | Length (mm) | DN | Comment | ||||

|---|---|---|---|---|---|---|---|---|

| 7500FG15-1,5 | 1,5 | 110 | 15 | |||||

| 7500FG20-2,5-130 | 2,5 | 130 | 20 | |||||

| 7500FG25-6 | 6 | 260 | 25 | |||||

| 7500FG40-10 | 10 | 300 | 40 | |||||

| Flanged performance, corded operation, installation in colder pipe lines | ||||||||

| AT-no | qp | Length (mm) | DN | Comment | ||||

|---|---|---|---|---|---|---|---|---|

| 7500FG15-1,5 | 1,5 | 110 | 15 | |||||

| 7500FG20-2,5-130 | 2,5 | 130 | 20 | |||||

| 7500FG25-6 | 6 | 260 | 25 | |||||

| 7500FG40-10 | 10 | 300 | 40 | |||||

| AT-number | Desciription |

|---|---|

| 7299-15INST | Installation kit to DN15: qp 1,5 |

| 7299-20INST | Installation kit to DN20: qp 2,5 |

| 7299-25INST | Installation kit to DN25: qp 6 |

| 7299-40INST | Installation kit to DN40: qp 10 |

| 7056A15 | Coupling DN15 (Also part in installation skit) |

| 7056-20 | Coupling DN20 (Also part in installation skit) |

| 7056-25 | Coupling DN25 |

| 7056-40 | Coupling DN40 |

| 7279-45 | Thermowell is used for threaded and flanged meters DN15-25 (is also part of an installation kit) |

| DN15-20 needs 1 thermowell and DN25 needs 2 thermowell | |

| 7279-52 | Thermowell is used for threaded and flanged meters DN 40 |

| To DN40 2 Thermowell are required | |

| 7279-85 | Thermowell is used for threaded and flanged meters DN 50-100 |

| To DN50-100 2 Thermowell are required |

| AT-no | Description |

|---|---|

| 7275EW-M | M-bus module |

| 7275EW-P | Pulse module |

| 7275EW-AN | Analog module |