Single jet turbine type meter, designed to measure cold drinking water, offering the capability to measure accurately a wide range of flow rates. Threaded connection,for horizontal mounting. Prepared for pulse/data sensor (M-bus)/radio type AT 7275CY.

| Dimension range | DN 20-40 |

|---|---|

| PN | 40 |

| Temperature range | Max 50 ºC |

| Material | Brass |

| Article number | Amount |

|---|---|

| AT 7051-20-4 | |

| AT 7051-25-6,3 | |

| AT 7051-40-16 | |

| AT 7275CY-KLF1 | |

| AT 7275KLF10 | |

| AT 7275CY-M | |

| AT 7275CY-M2 |

| Dimensionsområde | PN | Temperaturområde | Material |

|---|---|---|---|

G 3/4 - G 2 | 16 | + 1 ºC to + 50 ºC | Brass |

,MID-certificate, CE-marking

| Component | Material | |

|---|---|---|

| 1 | Body | Brass CW167N |

| 2 | Top | A.B.S |

| 3 | Measure probe | Poly propene |

| 4 | Gear | Ferrite |

UGE.35 Gauge for flow, pipe mounted with digital visual, accumulated value.

Cold water meter for horizontal mounting AT 7051....., Q3 .... m³/h, DN ...., PN 16, prepared for connection of pulse and M-Bus sensor Cyble

| AT 7051 | ||||||||||

| Permanent flow rate Q3 (m3/h) | 4 | 6,3 | 16 | |||||||

| Connection after fitting DN | 20 | 25 | 40 | |||||||

| A (build length) | 190 | 260 | 300 | |||||||

| B | 123 | 130 | 178 | |||||||

| C | 22,5 | 39 | 45 | |||||||

| D | 92 | 92 | 144 | |||||||

| Connection, meter G | 25 | 32 | 50 | |||||||

| Total height including. Cyble sensor | 165 | 172 | ||||||||

| Weight | 1,6 | 2,3 | 5,7 | |||||||

| Dimensions in mm, weight in kg | ||||||||||

The water meter is a dry single-jet meter with accuracy class R160 as a standard. The insert is made out of four units: counter, beaker, vane and sieve mantle. AT 7051 has two main components; the hydraulic that allows measurement of the water flow and the register that displays the measured water volume. Transmission interface between those components is achieved by a magnetic coupling.

Equipped with an upstream filter, AT 7051 is protected against impurities accidentally conveyed by water. The magnetic coupling transmission, is accompanied by an extra-dry register. Both gears and register are in a waterproof and air proof enclosure. The turbine is the only moving part of the meter in motion in water.

The meter is provided with a dial indicator for connection of remote reading module Cyble, with pulse or data output (M-Bus or wM-Bus ). See separate product sheet AT 7275CY.

Cyble is an inductive AMR-system (Automatic Reading System) for remote reading and transfer of meter data from the water meter to the measurement collection system. The Cyble-sensor's rotational frequency is read inductively through a metal fitted dial indicator. Remote reading of the type Cyble is not affected by any external magnet and therefore has high operational integrity.

Cyble-sensor can be mounted directly or at a later point, on the gauge's glass is prepared with attachment points with the help of the accompanying screws.

| DN 20 | DN 25 | DN 40 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

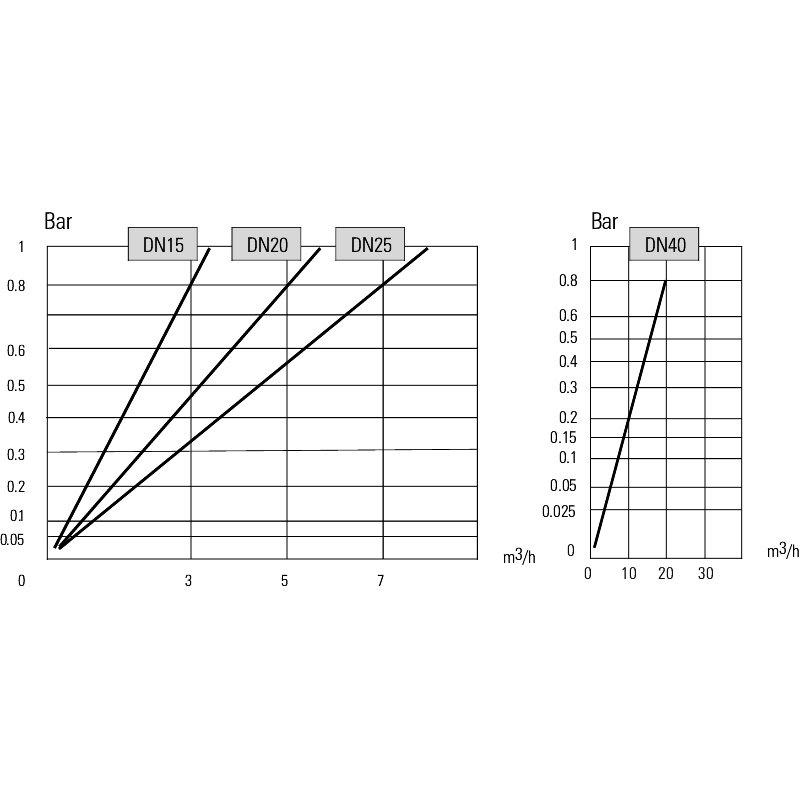

| Q3 | Permanent flow, m3/h (meter size) | 4 | 6,3 | 16 | ||||||

| Q1 | Minimum flow, l/h | 25 | 39,4 | 100 | ||||||

| Q2 | Transitaional flow, l/h | 40 | 63 | 160 | ||||||

| Q4 | Overload flow, m3/h | 5,0 | 7,9 | 20,0 | ||||||

| R | Ratio (Q3/Q1) (Given value is standard, Other R-values on request) | 160 | 160 | 160 | ||||||

| The table above describes the metrological properties according to Swedacs regulations for MID. | ||||||||||

| Largest allowed margin of error | |

| Flow range | Allowed margin of error |

|---|---|

| Q1 - Q2 | ± 5% |

| Q2 - Q4 | ± 2% |

Accessories

- Installation accessories, consoles and parallel couplings, se product sheet for AT 7358 , 7360A and AT 7056A.

Options

- Remote reading module, see separate product sheet AT 7275CY.

- Meter with its own number series.

| Water meter | Art.no (check valve incl. gasket ) |

|---|---|

| Q3 4 (DN20) | AT 7059A20 |

| Q3 6,3 (DN25) | AT 7059M25 |

| Q3 16 (DN40) | AT 7059M40 |

AT 7051 shall be mounted horizontal , but always with the number board upwards with accuracy R160.

To secure the water meter's long term drive, the installation should always be performed with water meter consol (see under accessories). Shut-off valves should always be mounted on the consoles in and output.

The backflow protection after the water meter should be a protection module type EA (controllable check valve) AT 1159 with shut-off valve mounted on the input side. Alternatively the cartridge check valve AT 7059 can be mounted on the meter's output.

Before the the meter can be mounted, it's important to clean flush the pipeline. Mount the meter with flow direction arrow in the right flow direction.

For installation of remote reading module, se product sheet 7275CY.

| AT 7050B (horizontal mounting) | |||

| Q3 | DN | Art.no | RSK-number |

|---|---|---|---|

| 4 | 20 | AT 7051-20-4 (Length 190 mm) | 5143849 |

| 6,3 | 25 | AT 7051-25-6,3 | 5143850 |

| 16 | 40 | AT 7051-40-16 | 5143851 |