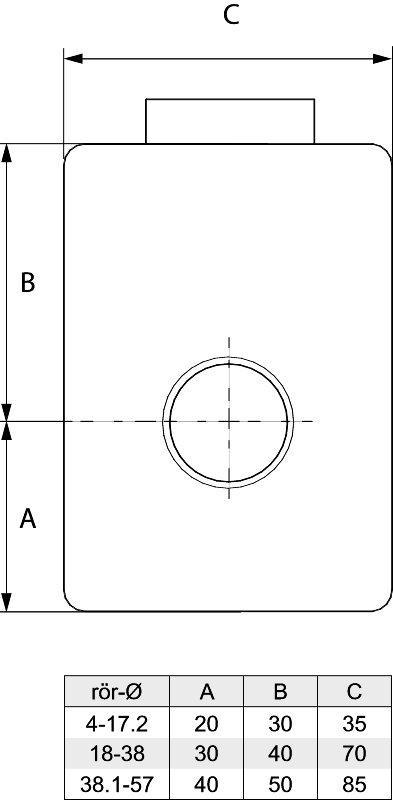

| Dimension range | PN | Temperature range | Material |

|---|---|---|---|

4-57 mm | - | -40°C to +150ºC | Stainless steel /Plastic |

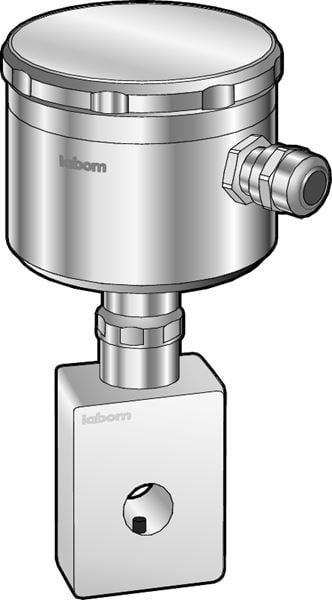

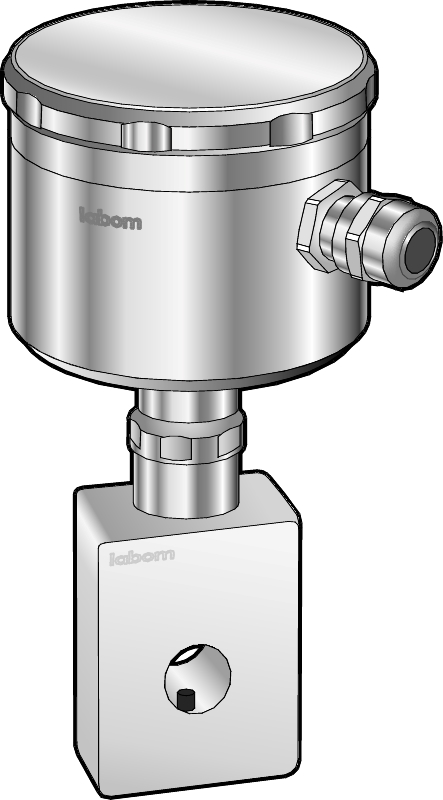

For measuring the surface temperature of pipes and control of processes. Used eg Of the life and pharmaceutical industry where there are greater hygiene requirements.

UBB.32 Temperature transmitter

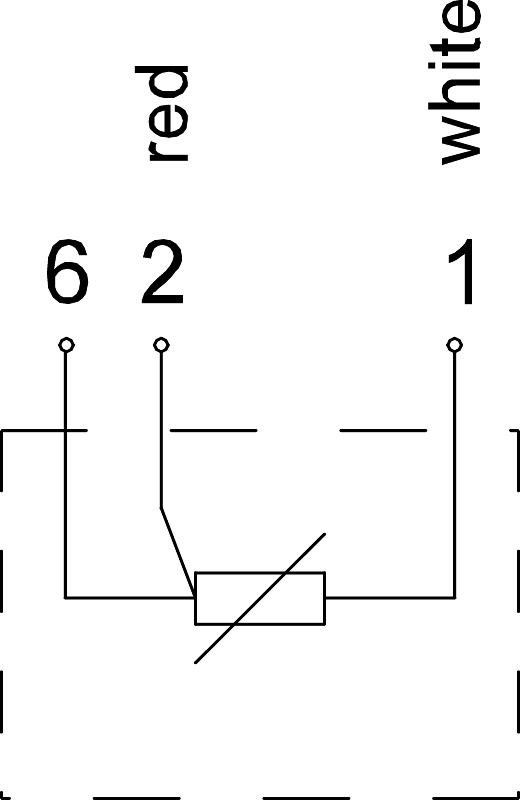

Continuous output signal 4-20 alt. Pt100 signal.

| 1 | Insulating material | Plastic |

| 2 | Heat transfer plate | Stailess steel 1.4305 |

| 3 | Neck | Stailess steel 1.4305 |

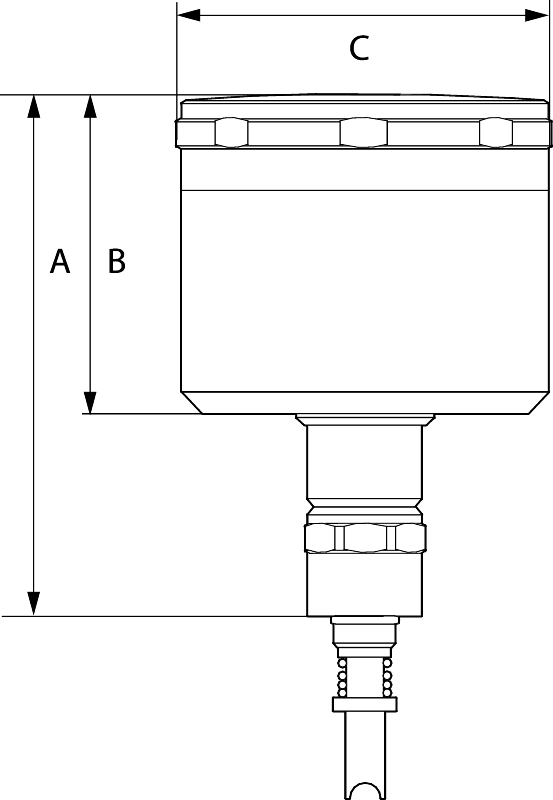

| A | 83,5 |

| B | 51 |

| C | 60 |

Temperature sensors primarily intended for hygiene applications where interference in the pipes is not desirable. Easily mounted on existing pipes. No welding required. The heat transfer between the PT100 sensor and the tube is achieved through a built-in contact system (a stainless steel ink). The PT100 sensor is protected by an insulating, removable block of heat-resistant plastic. Measurement technology PT 100, wire. Measurement range -40 ° C to + 150 ° C. Output PT 100 alternatively 4-20mA. The extremely small delay this method causes, compared to a traditional solution is usually negligible. See diagram.

| PT100 sensor | |

| Measuring range | -40ºC to +150ºC |

| Connection | 3-wire |

| Accuracy PT100 element | Class A acc. to EN 60751 |

| Protection class | IP65 |

| Pipe dimension | 4...57mm (outside diameter) |

| Electrical connection | Cable entry |

| Alternative oouput signal (stated upon ordering) | 4-20mA |

| Transmitter (option) | ||

| Supply voltage | 24VDC | |

| Connection | 2-wire | |

| Working temperature | -40°C to +85°C | |

| Output signal* | 4-20mA, invertable | |

| Response-time* | 1s (standard) | |

| Accuracy (RTD) | ≤ ±0,3 ºC | |

| *Wanted inverted signal or other respons time, specify this when ordering. | ||

As an option, the temperature sensor can be ordered with output 4-20mA. Measurement area is stated when ordering. Desired software for transmitter programming "Loop Link 5905" can be ordered separately..

The insulating plastic block consists of two parts and is mounted outside the tube by means of two hexagonal screws. It is important that the heat transfer plate is positioned against the pipe for best measurement results. The PT100 sensor can be mounted in any position but is advantageously fitted with the PT100 sensor underneath the tube, especially with steam or liquids.

| Example: AT 7780-33,7T | ||

| AT 7780 | 33,7 | T |

|---|---|---|

| Fig.no. | The pipes outer diameter | Transmitter |