Manometer with red warning indicator, R3/8 x 100. Class 2,5.

| Dimension range | DN 10 |

|---|---|

| PN | In short term load 90% of the scale value |

| Temperature range | -20ºC to +60ºC |

| Material | Plastic/Brass |

| Article number | Amount |

|---|---|

| AT 8305A10-4 | |

| AT 8305A10-6 | |

| AT 8305A10-10 | |

| AT 8305A10-16 |

| Dimension range | PN | Temperature | Material |

|---|---|---|---|

G 3/8 | At short term loading, 90% of scale value | -20°C to +60°C | Plastic/Stainless steel |

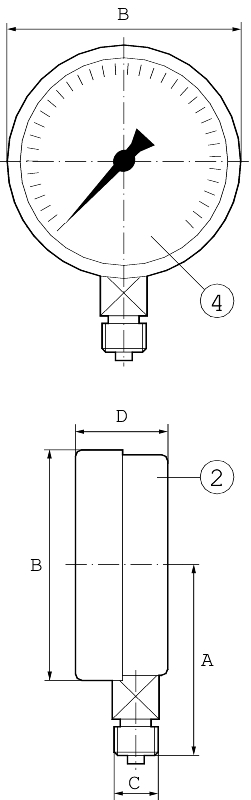

For indication of actual pressure in heating/cooling systems. AT 8305A is supplied with a red adjustable pointer on the scale.

UGC.31 Gauge for pressure

Pipe mounted, with analogue display of instantaneous value. Pressure gauge AT 8305A is provided with red indicator for highest allowed pressure. Class 2,5. Graded 0-... bar.

| AT 8305A | ||

|---|---|---|

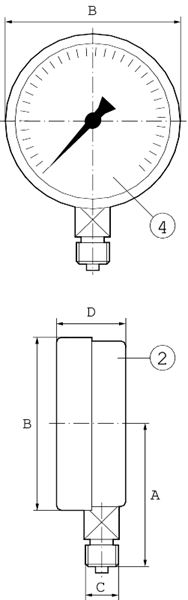

| 1 | Bourdon tube | Copper alloy |

| 2 | Body | Black plastic ABS |

| 3 | Measuring body | Copper alloy |

| 4 | Glass | Acrylic glass |

| Parts in contact with media made of copper alloy. |

| AT 8305A | ||

|---|---|---|

| A | 85,5 | |

| B | 100 | |

| C | G 3/8 | |

| D | 30 | |

| Measurements in mm. | ||

The pressure gauge is of the bourdon tube type, which has a circular formed tubular spring with an oval cross section. The pressure in the system influences the bourdon tube internally so that an increase in pressure tends to straighten it out. The free end of the bourdon tube gives a movement proportional to the internal pressure. The movement is then transferred via the measurement unit to a movement/indicated value on the scale. The pressure gauge has a red adjustable pointer to indicate the maximum allowable pressure.

| AT 8305A | |

|---|---|

| Media temperature | -40°C to +60°C |

| Ambiant Temperature | -20°C to +60°C |

| Accuracy class | 2,5% |

| Effects of Temperature | 0,4%/10°C |

| IP class | 54 |

| Max. working pressure | 3/4 of the scale value at rest load. 2/3 of the scale value at fluctuating loads. |

| Contact function | - |

| Supply voltage | - |

| Switch capacity | - |

| Electrical connection | - |

Pressure gauges with electrical contact in muted or industrial design upon request.

Pressure gauges shall be mounted so that they are easy to read and protected against vibration, heat, cold and high humidity. At high media temperatures water worm pipes shall be used. When pressure fluctuations and vibrations, damping liquid filled pressure gauge should be used.

The cables are labeled with numbers. Electrical installation according to schematic.

| Grading | AT.no. (standard) |

|---|---|

| 0-4 bar | 8305A-10-4 |

| 0-6 bar | 8305A-10-6 |

| 0-10 bar | 8305A-10-10 |

| 0-16 bar | 8305A-10-16 |