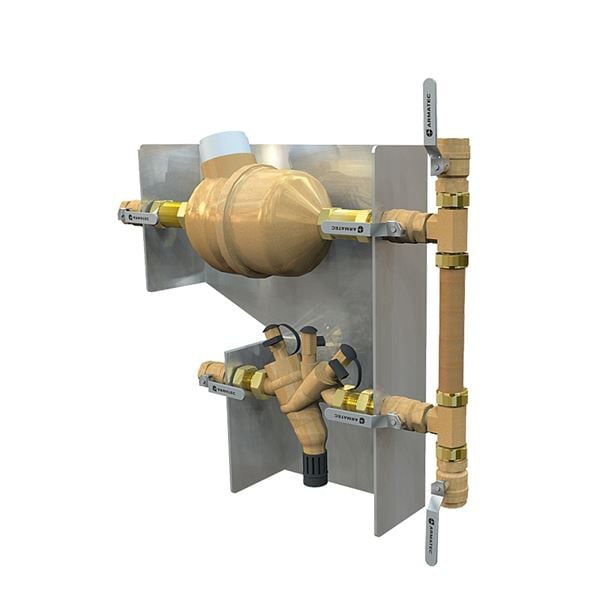

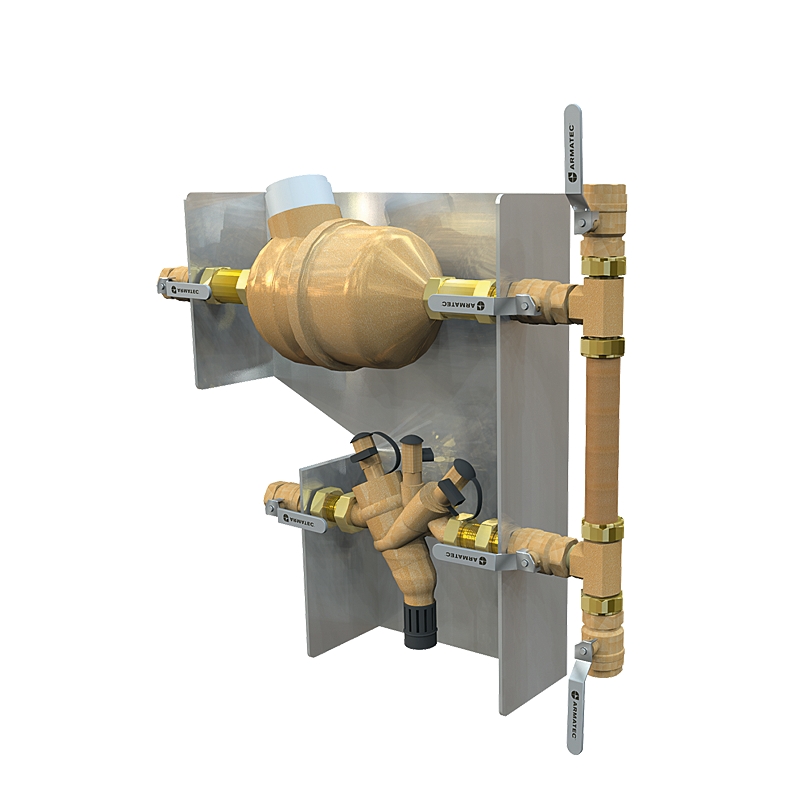

Protection module type BA for connection to automatic car wash including water gauge (complete unit for installation).

| Dimension range | G 1 1/4 - 1 1/2 |

|---|---|

| PN | 10 |

| Temperature range | 0ºC to 40ºC |

| Material | Combined unit |

| Article number | Amount |

|---|---|

| AT 1163-32 | |

| AT 1163-40 |

| Dimension range | PN | Temperature range | Material |

|---|---|---|---|

G 1 1/4 - 1 1/2 | 10 | 0 ºC to 40 ºC | Combined unit |

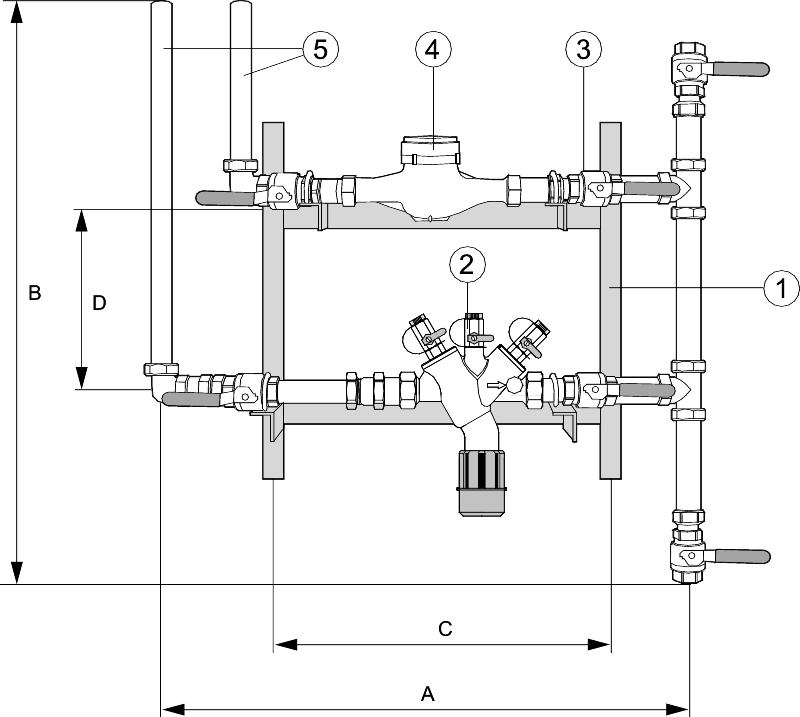

| 1 | Console | Stainless steel |

| 2 | Preventer type BA | Red brass |

| 3 | Ball valve | Brass |

| 4 | Water gauge | Brass |

| 5 | Pipes | Copper |

| Art. no. | A | B | Depth | C | D | Pipe | Drain | Weight | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C/C | C/C | Preventer | ||||||||||||||

| AT 1163-32 | 1000 | 1000 | 200 | 560 | 550 | Cu 35 | 50 | 53 | ||||||||

| AT 1163-40 | 1000 | 1000 | 200 | 560 | 550 | Cu 42 | 50 | 57 | ||||||||

| Dimensions in mm, weight in kg. | ||||||||||||||||

Backflow preventer type BA covers the risks up to fluid category 4 by connection of tap water. I.E. "Fluid that entails a health risk through presence of one or multiple toxic or very toxic substances or several radioactive, mutagenic or cancerous substances".

The preventer has double check valves and an intermediate chamber with draining. The preventer works with two different pressure zones, which affects the pressure loss over the two check valves. The intermediate chamber creates a safety zone towards the drinking water system. The pressure controlled intermediate chamber drains to the atmosphere during pressure loss in the upstream pipe line.

Preventer type BA prevents both siphon backflow and pressure overload backflow.

The complete backflow preventer consists of a protection module. The protection module contains a preventer type BA with an integrated dirt strainer. Shut-off valves for inlet and outlet included. It's an absolute demand that the backflow preventer is installed as a protection module. The car wash module is also provided with a water gauge for internal reading of consumption to a car wash machine.

For further information, see the product sheet, Backflow preventer AT 1168B, Ball valve AT 3605, Water gauge 7420.

| Art. no. | Unit | Capacity | Water gauge, |

|---|---|---|---|

| nominal flow | |||

| AT 1163-32 | Combine machine | 130 l/min, 4 bars flow pressure | qn 6 |

| AT 1163-40 | Double machine, washing path | 150-250 l/min, 4 bars flow pressure | qn 10 |

Insufficient or incorrect maintenance of a tap water installation, including backflow preventer, could result in a worsened tap water quality. Regular (yearly) maintenance of the protection module should therefore be done to secure the preventer's long term function. This is a demand according to the standard SS-EN 1717. The yearly control should be performed by a controller with the proper education who is approved by Armatec AB.

For all installed backflow preventer of the type BA yearly control routines be established and a control report should be sent to the water supplier.

Armatec's service technicians are specially trained and certified for reparation and service control of backflow preventer. We offer to perform the service control and make sure that the basis for necessary reports is done.

| DN | Application | AT-no | RSK-no |

| 32 | for combine machine | 1163-32 | 5021021 |

| 40 | for washing path | 1163-40 | 5021022 |