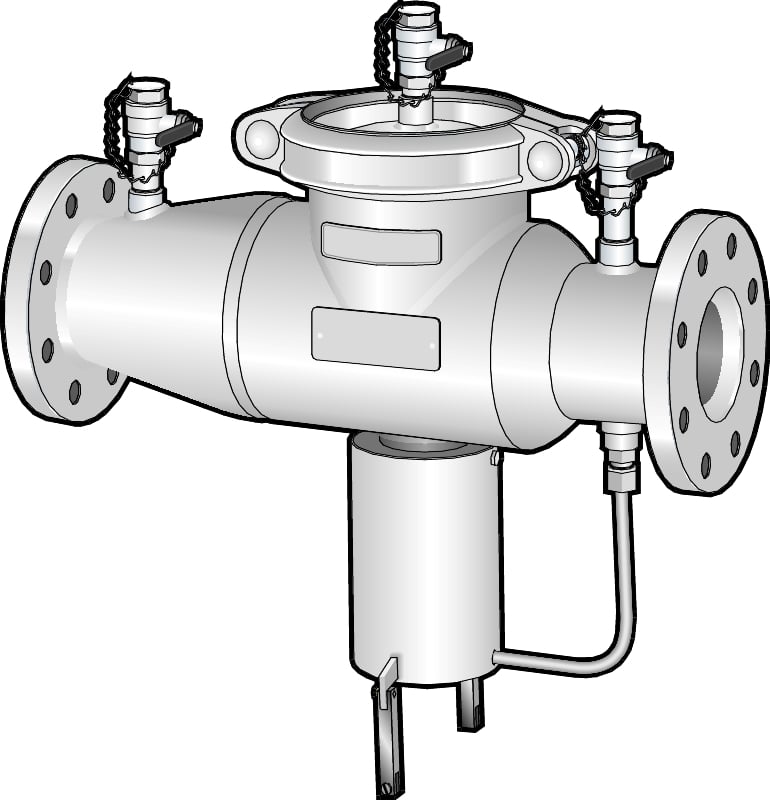

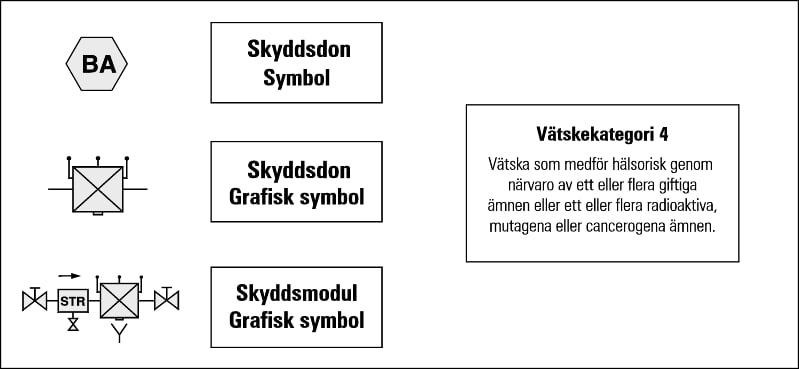

Protection module type BA with flanged connection for fluid category 4 according to SS-EN 1717.

| Dimension range | DN 65 - 200 |

|---|---|

| PN | 10 |

| Temperature range | 0ºC to 65ºC |

| Material | Gray iron / Stainless steel |

| Article number | Amount |

|---|---|

| AT 1167-65M | |

| AT 1167-80M | |

| AT 1167-100M | |

| AT 1167-150M | |

| AT 1167-200M | |

| AT 1167R65 | |

| AT 1167R80 | |

| AT 1167R100 | |

| AT 1167R150 |

| Dimension range | PN | Temperature range | Material |

|---|---|---|---|

DN 65-200 | 10 | 0ºC to 65ºC | Gray iron |

| DN 65-150 | 10 | 0ºC to 65ºC | Stainless steel |

| AT 1168B | AT 1167 | ||

|---|---|---|---|

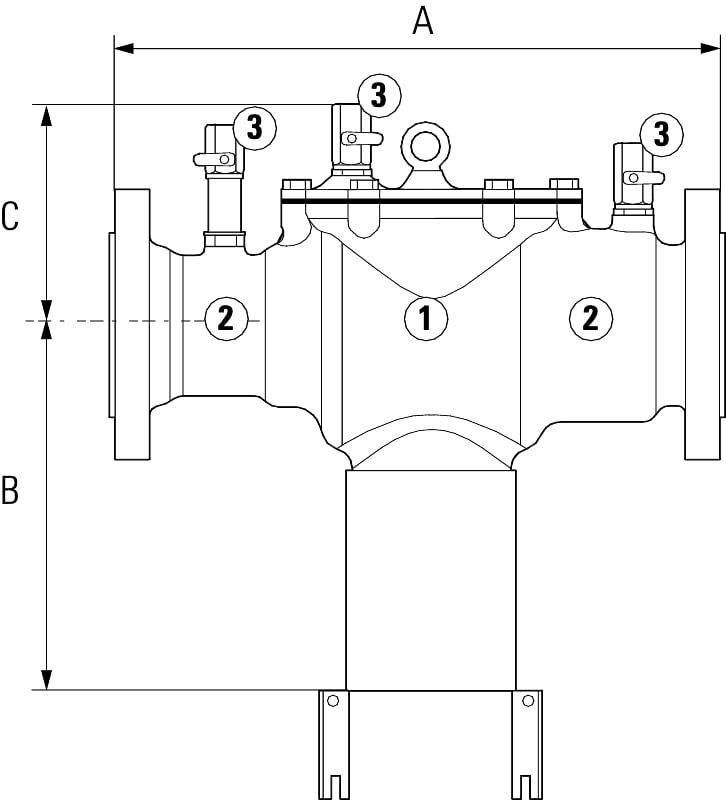

| 1 | Housing | Surface coated gray iron | Stainless steel EN 1.4571 |

| 3 | Checkvalve | Brass | Stainless steel EN 1.4305 |

| 4 | Control valves | Nickel-plated brass | Nickel-plated brass |

| 5 | Membrane, sealings | EPDM | EPDM |

| AT 1167B | A | B | C | Connection | Weight | Build length |

|---|---|---|---|---|---|---|

| DN | draining | preventer | module | |||

| 65 | 356 | 246 | 155 | DN 150 | 23,9 | 738 |

| 80 | 440 | 275 | 173 | DN 150 | 32,7 | 842 |

| 100 | 530 | 296 | 201 | DN 150 | 44,6 | 984 |

| 150 | 630 | 314 | 230 | DN 150 | 70,9 | 1222 |

| 200 | 763 | 346 | 272 | DN 150 | 114,1 | 1483 |

| AT 1167R | A | B | C | Connection | Weight | Build length | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | draining | preventer | module* | |||||||||

| 65 | 559 | 270 | 245 | DN 150 | 32,0 | 1189 | ||||||

| 80 | 559 | 270 | 245 | DN 150 | 32,5 | 1229 | ||||||

| 100 | 559 | 270 | 245 | DN 150 | 33,0 | 1289 | ||||||

| 150 | 695 | 300 | 285 | DN 150 | 57,0 | 1875 | ||||||

| Dimensions in mm, weight in kg | ||||||||||||

| *) Total build length is the sum of ingoing valves, gaskets are not included. | ||||||||||||

Backflow preventer type BA covers the risks up to fluid category 4 by connection of tap water. I.E. "Fluid that entails a health risk through presence of one or multiple toxic or very toxic substances or several radioactive, mutagenic or cancerous substances".

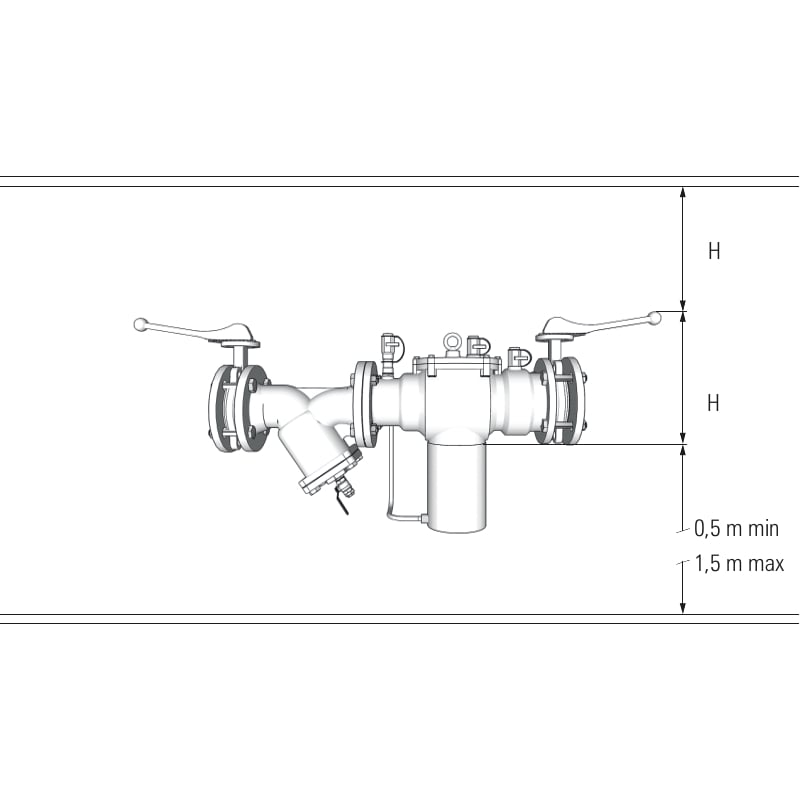

The preventer has double check valves and an intermediate chamber with draining. The preventer works with three different pressure zones. The pressure in zone 1 is higher than in zone 2, which is higher than zone 3. A drain valve is connected in zone 2 and is opened when the pressure difference between zone 1 and zone 2 falls below 0,14 bar. The water in zone 2 is drained to the atmosphere. That way strainer and pressure overload backflow in the system is prevented.

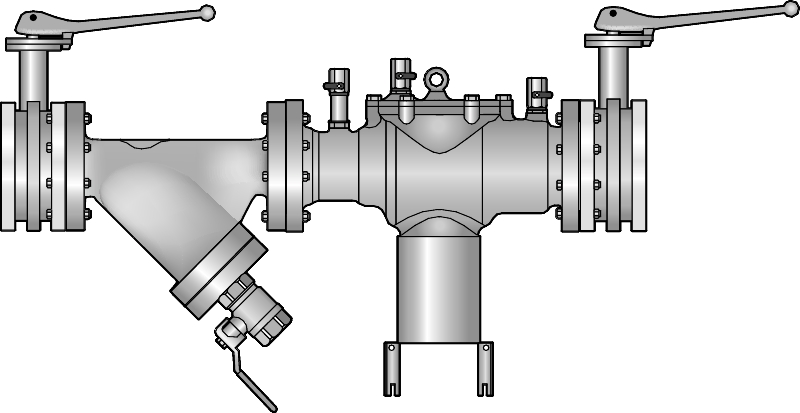

The backflow preventer should be installed as a complete proteciton module. The protection module contains a preventer type BA together with an integrated dirt filter. Shut-off valves for inlet and outlet included. It's an absolute demand that the back flow preventer is installed as a protection module.

Insufficient or incorrect maintenance of a tap water installation, including backflow preventer, could result in a worse tap water quality. Regular (yearly) maintenance of the protection module should therefore be done to secure the preventer's long term function. This is a demand according to the standard SS-EN 1717. The yearly control should be performed by a controller with the proper education who is approved by Armatec AB.

For all installed backflow preventer of the type BA yearly control routines be established and a control report should be sent to the water supplier.

Armatec's service technicians are specially trained and certified for reparation and service control of backflow preventer. We offer to perform the service control and make sure that the basis for necessary reports is done.

Insufficient or incorrect maintenance of a tap water installation, including backflow preventer, could result in a worsened tap water quality. Regular (yearly) maintenance of the protection module should therefore be done to secure the preventer's long term function. This is a demand according to the standard SS-EN 1717. The yearly control should be performed by a controller with the proper education who is approved by Armatec AB.

For all installed backflow preventer of the type BA yearly control routines be established and a control report should be sent to the water supplier.

Armatec's service technicians are specially trained and certified for reparation and service control of the backflow preventer. We offer to perform the service control and make sure that the basis for necessary reports is done.

Manufacturing, DN, PN, flow direction arrow, manufacturer and manufacturing number.

Separate control marking plate.

| Complete protection module (gray iron) | ||

| DN | AT-no | RSK-no |

|---|---|---|

| 65 | 1167-65M | 5021029 |

| 80 | 1167-80M | 5021030 |

| 100 | 1167-100M | 5021031 |

| 150 | 1167-150M | 5021032 |

| 200 | 1167-200M | 5021033 |

| Only preventer (gray iron) | |

| DN | oAT-nr |

|---|---|

| 65 | 1167B65 |

| 80 | 1167B80 |

| 100 | 1167B100 |

| 150 | 1167B150 |

| 200 | 1167B200 |

| Only preventer (Stainless steel) | |

| DN | AT-no |

|---|---|

| 65 | 1167R65 |

| 80 | 1167R80 |

| 100 | 1167R100 |

| 150 | 1167R150 |