Pneumatic single acting actuator for on-off and control of ball valves and butterfly valves or where 90° rotation is required.

| Torque | 10 Nm to 3145 |

|---|---|

| Drive | Pneumatic/spring |

| Suitable for article | AT3502, AT3507, AT3533S, AT3534S, AT3582, AT3585, AT3590, AT2282, AT 2310-2319 |

| Article number | Amount |

|---|---|

| AT 3831-20 | |

| AT 3831-40 | |

| AT 3831-80 | |

| AT 3831-130 | |

| AT 3831-200 | |

| AT 3831-300 | |

| AT 3831-500 | |

| AT 3831-850 | |

| AT 3831-1200 | |

| AT 3831-1750 | |

| AT 3831-2100 | |

| AT 3831-2500 | |

| AT 3831-4000 |

Solenoid valve connection and actuator top acc. to VDE/VDI 3845 (NAMUR).

Mounting flange and stem square drilled acc. to ISO 5211 and DIN 3337.

CE-marking

The actuators meet the demands from PED, AFS 1999:4 §8, The Pressure Equipment Directive and the machine directive, MD 2006/42/EG and ATEX 94/9/EC.

Actuators in the sizes 10 to 300 are classified as category SEP in accordance with the demands from PED 97/23/EC.

Actuators in the sizes 500 to 4000 are classified as category 1.

All Actregs pneumatic actuators are classified for use in potentially explosive atmospheres as Group II Category 2, suitable for zones 1, 2, 21 and 22 in accordance with Annex VIII of Directive 94/9/CE (ATEX).

Certificate from Germanischer Lloyd (GL). Lloyd's register of shipping can be delivered as an option.

| Detail | No | Material | Surface treatment | |

|---|---|---|---|---|

| 1 | Body | 1 | Aluminium | Anodized C3 according to EN-ISO 12944-2 |

| 2 | Wing | 1 | Carbon steel | Electroless nickel plated. |

| 3 | Springs | 2-8 | Steel | Pre-stressed |

| 4 | End caps | 2 | Aluminium | Epoxy coated |

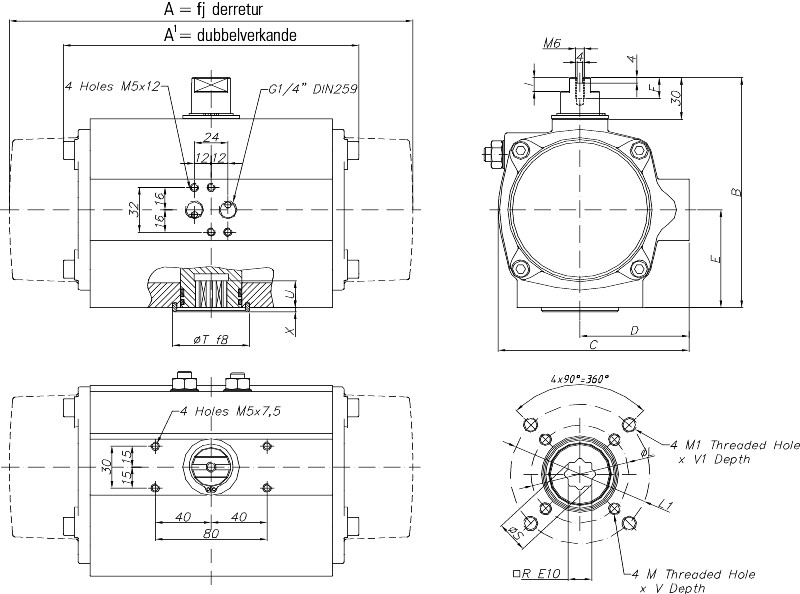

Actuator size | 3830 | 3831 | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | A´ | B | C | D | E | F | I | |||||||||||||||||||

| 10 | 100 | 76 | 56 | 33 | 23 | 9 | 6 | |||||||||||||||||||

| 20 | 145 | 163 | 96 | 76 | 48 | 34 | 9 | 6 | ||||||||||||||||||

| 40 | 158 | 195 | 115 | 91 | 56 | 45 | 9 | 6 | ||||||||||||||||||

| 80 | 177 | 217 | 137 | 111 | 66 | 55 | 12 | 12,5 | ||||||||||||||||||

| 130 | 196 | 258 | 147 | 122 | 71 | 60 | 15 | 8 | ||||||||||||||||||

| 200 | 225 | 299 | 165 | 135,5 | 78 | 70 | 15 | 10 | ||||||||||||||||||

| 300 | 273 | 348,5 | 182 | 152,5 | 86 | 80 | 16 | 12 | ||||||||||||||||||

| 500 | 304 | 397 | 199 | 173 | 96 | 85 | 17 | 15 | ||||||||||||||||||

| 850 | 372 | 473 | 221 | 191,5 | 106 | 98 | 15 | 15 | ||||||||||||||||||

| 1200 | 439 | 560 | 249 | 212,5 | 116 | 114 | 16 | 15 | ||||||||||||||||||

| 1750 | 461 | 601 | 280 | 242,5 | 131 | 130 | 16 | 15 | ||||||||||||||||||

| 2100 | 504 | 698 | 313 | 276,5 | 148 | 147 | 16 | 15 | ||||||||||||||||||

| 2500 | 518 | 738 | 383 | 356 | 177,5 | 176,5 | 16 | 15 | ||||||||||||||||||

| 4000 | 630 | 940 | 434 | 415 | 213 | 201 | 16 | 15 | ||||||||||||||||||

| Measurements in mm, weight in kg | ||||||||||||||||||||||||||

Actuator size | Weight | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R | ØS | ISO | ØL | MxV | ØT | X | U | 3830 | 3831 | |||||||||||||||||||

| 10 | 9 | 12,5 | F03 | 36 | M8x5 | - | - | 12 | 0,64 | |||||||||||||||||||

| 20 | 11 | 14,7 | F04 | 42 | M5x10 | 30 | 3 | 17 | 1,4 | 1,54 | ||||||||||||||||||

| 40 | 11 | 14,7 | F04 | 42 | M5x10 | 30 | 3 | 17 | 2,1 | 2,32 | ||||||||||||||||||

| 80 | 17 | 22,5 | F05/07 | 50 | M6x10 | 55 | 3 | 19 | 3 | 3,65 | ||||||||||||||||||

| 130 | 17 | 22,5 | F05/07 | 70 | M6x10 | 55 | 3 | 22 | 3,8 | 4,8 | ||||||||||||||||||

| 200 | 17 | 22,5 | F07/10 | 70 | M10x16 | 55 | 3 | 23 | 5,6 | 7,3 | ||||||||||||||||||

| 300 | 22 | 28,5 | F07/10 | 70 | M8x14 | 70 | 3 | 29 | 8,5 | 10,8 | ||||||||||||||||||

| 500 | 22 | 28,5 | F10 | 102 | M10x16 | 70 | 3 | 32 | 11,21 | 15,36 | ||||||||||||||||||

| 850 | 27 | 36,5 | F10/12 | 102 | M10x17 | 85 | 3 | 40 | 16,9 | 22,2 | ||||||||||||||||||

| 1200 | 36 | 48,5 | F10/14 | 102 | M10x17 | 100 | 4 | 49 | 25,8 | 34,3 | ||||||||||||||||||

| 1750 | 36 | 48,5 | F14 | 140 | M16x26 | 100 | 4 | 50 | 32,5 | 46 | ||||||||||||||||||

| 2100 | 46 | 60,2 | F16 | 165 | M20x26 | 130 | 4 | 50 | 49,7 | 68 | ||||||||||||||||||

| 2500 | 46 | 60,2 | F16 | 165 | M20x29 | 130 | 4 | 58 | 69,6 | 99,9 | ||||||||||||||||||

| 4000 | 55 | 72,5 | F16/25 | 165 | M20x30 | 200 | 4 | 60 | 129,4 | 182,9 | ||||||||||||||||||

| Measurements in mm, weight in kg | ||||||||||||||||||||||||||||

Actuator with linear torque curve. Three point controlled of the pistons for low friction between the body and pistons. Mounting holes according to ISO 5211 and DIN 3337, for standardized mounting to the valve. End caps with adjustable screws for stroke length (5°). Mechanic end points as a standard. The piston force is transfered through the rotary axle to the valve stem (90° + 1°-0,5°). Actuator top and solendoid valve connection according to NAMUR (VDE/VDI 3845).

Actuators Actreg AT 3831 single acting:

The actuator is provided as a standard with spring closing function. If a spring opening function is required this has to be stated when ordering.

| Pressure: | Supply pressure max 8 bar (e). Higher pressure on demand. |

| Temperature: | -30°C to +100°C. Other ranges on request. |

| Manoeuvre medium: | Air or inert gases, purity at least 40 micron. |

| (No requirements of mist lubrication). Oil or water. |

| Actuator | Air Pressure (bar) | |||||||

|---|---|---|---|---|---|---|---|---|

| Standard spring set | 6 | 7 | 8 | Spring return | ||||

| Start | Stop | Start | Stop | Start | Stop | Start | Stop | |

| AT 3831-20 | 14 | 10 | 17 | 13 | 20 | 17 | 11 | 7 |

AT 3831-40 | 26 | 17 | 33 | 24 | 40 | 30 | 28 | 17 |

| AT 3831-80 | 51 | 37 | 64 | 50 | 77 | 63 | 47 | 30 |

| AT 3831-130 | 80 | 64 | 99 | 84 | 119 | 103 | 64 | 45 |

| AT 3831-200 | 113 | 84 | 142 | 113 | 172 | 143 | 107 | 73 |

| AT 3831-300 | 190 | 126 | 238 | 175 | 287 | 223 | 193 | 119 |

| AT 3831-500 | 283 | 205 | 355 | 277 | 427 | 349 | 268 | 177 |

| AT 3831-850 | 488 | 367 | 607 | 487 | 727 | 607 | 412 | 271 |

| AT 3831-1200 | 698 | 502 | 871 | 675 | 1044 | 848 | 631 | 400 |

| AT 3831-1750 | 877 | 578 | 1113 | 813 | 1348 | 1049 | 983 | 631 |

| AT 3831-2100 | 1276 | 825 | 1638 | 1187 | 2000 | 1549 | 1347 | 896 |

| AT 3831-2500 | 2454 | 1861 | 3031 | 2438 | 3608 | 3015 | 1882 | 1184 |

| AT 3831-4000 | 3312 | 2142 | 4115 | 2945 | 4423 | 3254 | 3145 | 1769 |

| Actuator | Operating time in s. at 8 bar ADA/ASR | Cylinder volume in liters | |||||

|---|---|---|---|---|---|---|---|

| Open | Close | Open | Close | ||||

| 10 | 0,03 | 0,07 | 0,035 | 0,028 | |||

| 20 | 0,04 / 0,12 | 0,09 / 0,18 | 0,13 | 0,09 | |||

| 40 | 0,08 / 0,2 | 0,08 / 0,29 | 0,27 | 0,23 | |||

| 80 | 0,11 / 0,27 | 0,1 / 0,4 | 0,64 | 0,47 | |||

| 130 | 0,15 / 0,32 | 0,15 / 0,5 | 0,77 | 0,76 | |||

| 200 | 0,15 / 0,5 | 0,22 / 0,6 | 1,19 | 1,2 | |||

| 300 | 0,3 / 0,7 | 0,4 / 0,85 | 1,96 | 1,73 | |||

| 500 | 0,4 / 0,9 | 0,5 / 1,1 | 2,95 | 2,74 | |||

| 850 | 0,8 / 2,2 | 0,9 / 2,6 | 4,7 | 3,86 | |||

| 1200 | 1,2 / 2,3 | 1,5 / 2,8 | 6,95 | 4,64 | |||

| 1750 | 1,8 / 2,8 | 2 / 3,2 | 9,8 | 9,3 | |||

| 2100 | 2,3 / 3,3 | 2,6 / 3,7 | 11,6 | 10,2 | |||

| 2500 | 2,8 / 3,8 | 3,1 / 4,2 | 32 | 25 | |||

| 4000 | 3 / 4,3 | 3,5 / 5 | 33,2 | 27,5 | |||

| Actuator size | 20 | 40 | 80 | 130 | 200 | 300 | 500 | 850 | 1200 | 1750 | 2100 | 2500 | 4000 | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball valve | ||||||||||||||||||||||||||||

| AT 3502-3552 | DN | 8-20 | 25 | 32-40 | 50 | 65 | 80 | 100-125 | 150-250 | |||||||||||||||||||

| AT 3533A-3534A | DN | 10-15 | 20 | 25-32 | 40-50 | 65 | 80-100 | |||||||||||||||||||||

| AT 3582-3585 | DN | 15-20 | 25-32 | 40 | 50-65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | ||||||||||||||||

| Butterfly | ||||||||||||||||||||||||||||

| AT 2282 | DN | 80-100 | 125 | 150-200 | 250 | 300 | 350 | |||||||||||||||||||||

| vid D p 10 bar | ||||||||||||||||||||||||||||

| AT 2310-2344 | DN | 50-65 | 80 | 100 | 125-150 | 200 | 250-300 | 350-400 | 450 | 500 | 600-700 | |||||||||||||||||

| vid D p 10 bar | ||||||||||||||||||||||||||||

The dimensioning is general and based on an available operational pressure 6 bar. The table does not take variations in operational conditions in to account. The conditions could impact the torque. Dimensioning for abnormal operational conditions can be acquired on demand. This also applies to AT 3810. | ||||||||||||||||||||||||||||

Accessories

The actuator should be disconnected electrically and pneumatically before assembly or dissassembly is started. The actuator should be mounted with even spaced distances.

Spare parts

The repair kit includes the neccessary soft parts.

Article number, series number, max allowed operation pressure.

Manufacturer

CE-marking

| Example: AT 3830-40/ 3831-40 | ||

| AT 3831 | 40 | |

| Fig. nr | Size |